(3)

(4)

(5)

(6)

(7)

(8)

(9)

(10)

(11)

(12)

TM9-2815-202-34

Injector body

Inspect injector body (21) threads, bushing seating surface, and fuel connector gasket

sealing surfaces for damage. Inspect rack hole, body seal ring sealing surface, clamp radius,

and dowel pin. Replace if necessary.

Fuel connectors

Check condition of jumper line sealing surfaces, copper gasket sealing surfaces, and fuel

connector (3) threads. Replace if necessary.

Control rack

(a) Check injector control rack (24) for straightness, rack teeth for damage, and notch in

clevis for wear. Check rack for nicks, burrs, rust, and hardness.

(b) Notch in clevis should be 0.3125 to 0.3145 inch.

Gear and gear retainer

Inspect gear (23) and gear retainer (22) for nicks, burrs, or rust. Check gear teeth for wear.

Bushing

Check bushing lapped sealing surface for scratches and bushing internal diameter for

scoring. Observe condition of dowel pin. Check for corrosion and varnish. Replace if

necessary.

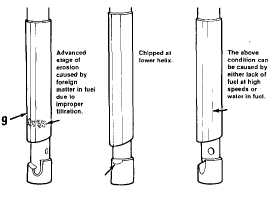

Plunger

Check plunger (9) for corrosion or varnish, scoring, scratching or wear, and chips along

edge of helix.

Check valve and check valve cage

(a) Inspect for cracks and scratches on lapped surfaces. Also inspect for corrosion, varnish,

and wear.

(b) Measure thickness of check valve (18) and check

thickness is 0.163 inch and minimum check valve

Valve spring

Check valve spring (16) for wear on coil ends, broken

valve cage (17). Minimum cage

thickness is 0.022 inch.

coil ends, and notches under coil

ends. Check for corrosion, nicks, and erosion on inside at armroximatety 1 1/2 coils from

end. Replace if necessary.

Spring seat

Check spring seat (15) surfaces for wear. Replace

if necessary.

Spring cage

(a) Inspect spring gage (14) for

cracks, corrosion or varnish, and

scratches on lapped sealing

surfaces. Inspect spring set

surface and needle valve seating

surface for wear.

(b) Measure thickness of spring cage. Minimum thickness is 0.602 inch.

4-227

|

|