TM 9-2815-202-34

4-40. FUEL INJECTOR ASSEMBLY REPAIR (Cont)

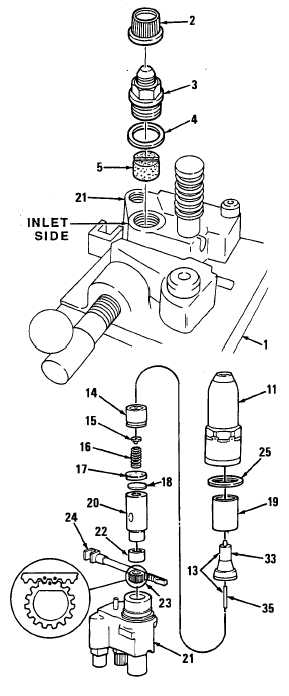

e. Assembly

(1) Secure injector body (21) infolding fixture(1).

(2) install filter (5) in inlet port of body (located above injector rack). Position filter with dimple end

down and slotted end up. No filter is required at outlet port.

(3) Install two gaskets (4) and two fuel connectors (3) to injector body. Lubricate connector threads

with engine oil before installation. Torque connectors to 70 Ib-ft (95 N-m) (blued components)

or to 62 Ib-ft (84 N-m) (mixed and nonblued components).

(4) Install two shipping caps (2) to connectors (3) to prevent dirt from entering injector.

(5) Support injector body assembly, bottom

end up, in holding fixture.

(6) Install seal ring (25) onto shoulder of

injector body (21 ).

(7) Slide injector control rack (24) into injector

body (21 ).

(8) Look into injector body bore and move

control rack (24) until you see two drill

marks on rack. Hold rack in this position.

(9) Place gear (23) in injector body so that

marked tooth on gear is engaged between

two marked teeth on control rack (24).

(10) Place gear retainer (22) on top of gear (23).

(11) Aline locating pin in bushing (20) with slot in

injector body (21). Slide end of bushing into

place.

(12) Install spill deflector (19) over barrel of

bushing (20).

NOTE

Perform needle valve opening

pressure test [ref. step f.(5)] at this

time before completing assembly.

(13) Place check valve (18) centrally on top of

bushing (20).

(14) Place check valve cage (17), flat side up,

over check valve (18) and against bushing

(20). Check valve cage must not rest on

check valve.

(15) Insert spring seat (15) in valve spring (16).

Install assembly on check valve cage (17)

with seat up.

4-230

Change 1

|

|