(16)

(17)

(18)

(19)

(20)

(21)

(22)

(23)

(24)

(25)

TM9-2815-202-34

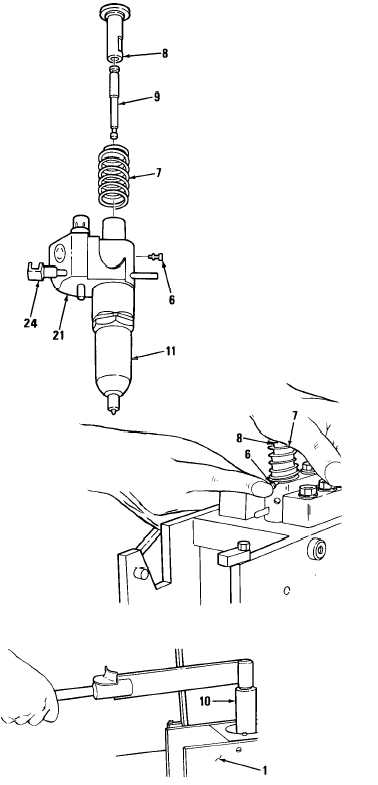

Place spring cage (14) over spring seat (15) and spring (16).

Insert needle valve (35) into spray tip (33) with tapered end down. Place spray tip assembly

(13) on top of spring cage (14) with quill end of needle valve in hole in spring cage.

Lubricate threads on injector nut (11) with engine oil and carefully thread nut on injector

body. Tighten nut as tight as possible by hand.

Turn injector over and push rack (24) all way in.

Place follower spring (7) on injector body

Slide head of plunger (9) into follower

(8).

Aline slot in follower (8) with stop pin

hole in injector body (21).

Aline flat side of plunger (9) with flat in

gear.

Insert free end of plunger (9) in

injector body (21).

Place stop pin (6) in slot on injector

body (21 ). Rotate spring (7) so flat

part of end coil is clear of pin (6).

Then push pin in place while pressing

down on follower (8). Once in place,

rotate spring (7) so flat on end coil is

positioned over pin.

CAUTION

Do not exceed specified torque. Otherwise,

nut may be stretched and result in improper

sealing of lapped surfaces in overhauled

injector.

NOTE

After assembling fuel injector,

always check area between nut and

body. If seal is still visible after nut is

torqued, try another nut and seal.

(21).

(26) With injector in holding fixture (1) and

using injector nut socket (10), torque

injector nut (11) to 80 Ib-ft (108 N-m)

for blued components or 50 Ib-ft

(68 N-m) for nonblued components or

65 Ib-ft (88 N-m) for mixed

components.

4-231

|

|