TM 9-2815-202-34

4-43. WATER PUMP REPAIR (Cont)

WARNING

Compressed air used for cleaning

purposes will not exceed 30 PSI.

Use only with effective chip guarding

and personal protective equipment

(goggles/shield, gloves, etc.).

(2)

(3)

(4)

(5)

(6)

Dry all parts with compressed air.

Inspect pump impeller for cracks, burrs, or

damage. If ceramic insert is damaged,

replace pump impeller.

Inspect housing and cover for cracks,

wear, or damage.

Inspect shaft for scores, discoloration, or

damage.

Inspect inner and outer bearings for pits,

discoloration, or damage.

c. Assembly

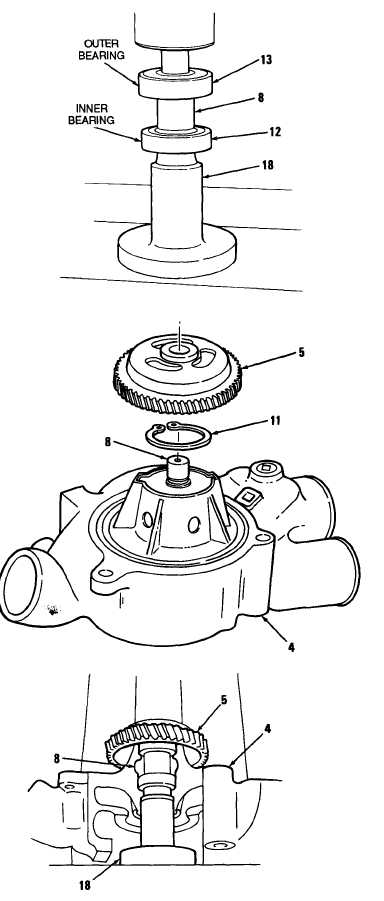

(1) Lubricate bearings (12 and 13) inner

surfaces and shaft (8) bearing surfaces

with engine oil.

CAUTION

When installing bearings, support inner

race only or damage to bearing may result.

(2)

(3)

(4)

(5)

(6)

4-264

Using installer (18), press inner bearing

(12) and outer bearing (13) onto shaft (8).

Support pump body (4) with cover side

down, and press bearings and shaft into

pump body.

Install lock ring (11) in groove of shaft (8).

Using installer (18), press gear (5) onto

impeller end of shaft (8) until gear is flush

with end of shaft.

Lubricate new oil seal (14) and shaft (8)

seal surface with engine oil.

|

|