TM 9-2815-202-34

5-37. CYLINDER HEAD REPAIR (Cont)

CAUTION

Do not use fuel oil to clean cam followers. It will wash away lubricating oil and cause

scoring of cam roller bushing at startup.

(b)

(c)

(d)

Wash cam followers with engine oil and wipe dry. Examine cam follower rollers for pitting,

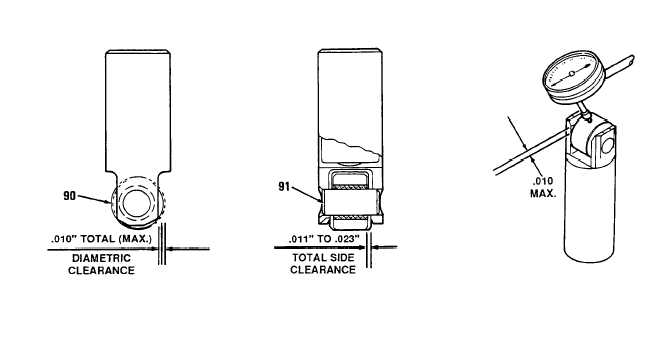

scoring, and flat spots. Rollers (90) must turn freely on their pins (91).

Using a dial indicator and holding fixture, measure total diametric clearance on cam follower

roller. Secure cam follower assembly in a vise or other holding device and place dial

indicator needle against outside diameter of roller. Obtain total clearance by moving roller in

crosswise direction. Maximum clearance is 0.010 inch.

Using a feeler gage, measure side clearance on cam follower. Insert gage between end of

roller and leg of cam follower body. Side clearance must be 0.015 to 0.023 inch.

(e) If necessary, install new cam follower rollers and pins as follows:

1. Clamp cam follower holding fixture (92) in a vise and place cam follower in groove at top

of assembly with cam follower pin resting on top of small plunger in holding assembly.

5-50

C h a n g e 1

|

|