TM9-2815-202-34

5.1-36. TURBOCHARGER REPAIR (Cont)

CAUTION

(4)

When polishing surfaces, use silicone carbide abrasive cloth for aluminum parts and crocus

cloth for steel parts.

Minor surface damage may be burnished or polished away.

c. Inspection

(1)

(2)

(3)

(4)

(5)

(6)

(7)

Inspect all parts for signs of damage, corrosion, or deterioration. Check for nicked, crossed, or

stripped threads.

Check turbine wheel for nicks, rubbing, and wear.

Inspect shaft for signs of scoring, scratches, or bearing seizure.

Check compressor wheel for signs of rubbing or blade damage. Check to see wheel bore is not

galled.

Inspect seal parts for signs of rubbing or

scoring of running faces.

Inspect backplate for wear or damaged

bore.

Inspect center housing for contact with

rotating parts.

d. Assembly

(1)

(2)

(3)

(4)

(5)

(6)

5-98

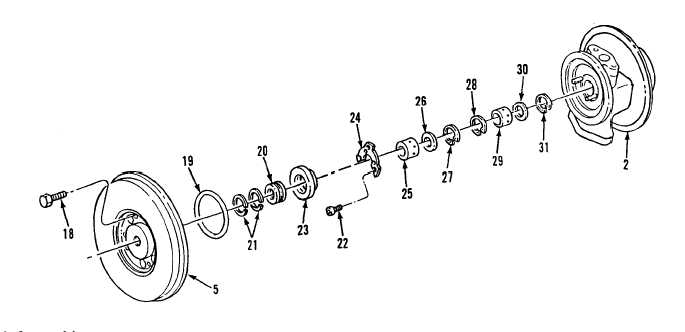

Lubricate bearing (25) and bearing (29) with engine oil.

Install inner retaining ring (31), bearing washer (30), bearing (29), and outer retaining ring (28)

in compressor end of center housing (2).

Install retaining ring (27), bearing washer (26), and bearing (25) in compressor end of center

housing (2).

Lubricate thrust collar (23) and thrust washer (24) with engine oil.

Insert thrust collar (23) into thrust washer (24) and install thrust collar, thrust washer, and three

self-locking screws (22) in center housing (2). Torque screws to 30-35 lb-in (3.4-3.9 N-m).

Install seal ring (19) in groove at compressor end of center housing (2).

Change 1

|

|