TM 9-2815-202-34

5.1-36. TURBOCHARGER REPAIR (Cont)

(12)

(13)

(14)

(15)

(16)

(17)

(18)

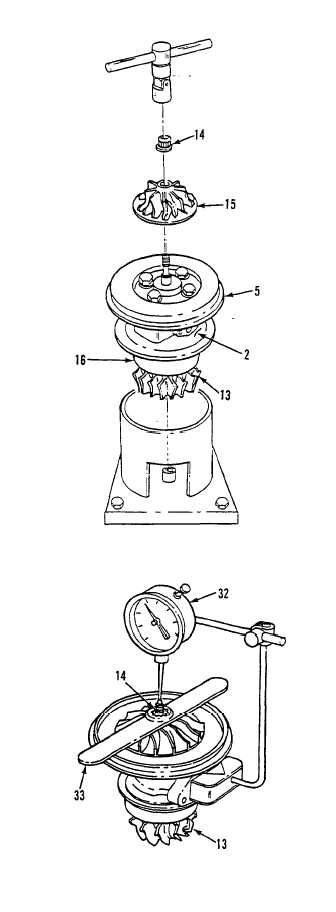

Place turbine wheel shaft assembly

(13), shroud (16), center housing (2),

and backplate (5) upright in

turbocharger holding fixture.

With compressor wheel (15) at room

temperature, position it over turbine

wheel shaft assembly (13).

CAUTION

When torquing compressor

wheel nut on shaft, use two

universal joints connected in

tandem or a single universal joint

and a universal socket to

prevent bending turbine wheel

shaft.

Lubricate shaft threads of turbine wheel

shaft assembly (13) and wheel face on

compressor wheel (15) with engine oil.

Install self-locking nut (14). Torque nut

to 125-150 lb-in (14-17 N-m) to seat

compressor wheel against thrust

spacer.

Loosen self-locking nut (14) and inspect

nut face and front face of compressor

wheel to insure they are smooth and

clean.

Torque self-locking nut (14) to 35-55

lb-in (4-6 N-m).

Attach magnetic base dial indicator (32)

to center housing.

Place impeller nut box wrench (33) on

impeller nut (14) and position dial

indicator on tip of turbine shaft

assembly (13). Set dial indicator to zero.

Tighten nut to obtain shaft stretch of

0.009-0.010 inch.

5-100

Change 1

|

|