|

|

|

|

|

TM 9-2815-202-34

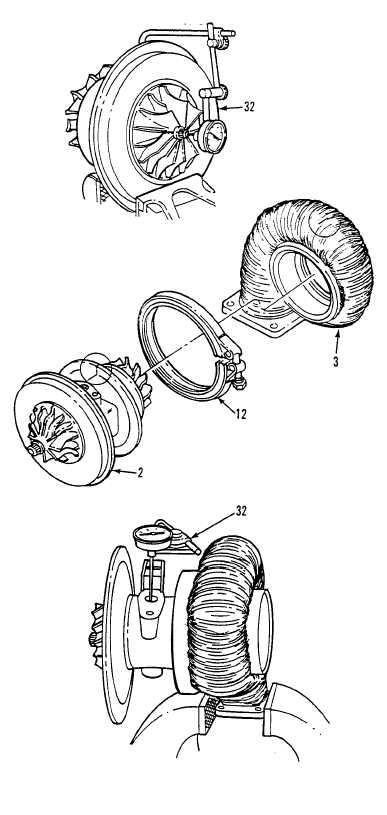

(19) Check bearing axial end play as follows:

(a) Clamp center housing assembly in

soft-jawed vise.

(b) Fasten magnetic base dial indicator

(20)

(21)

(22)

(32) to center housing with indicator

tip resting on end of rotating shaft

on compressor side.

(c) Move shaft axially back and forth by

hand. Total indicator reading should

be between 0.003 and 0.010 inch.

Repair or replace shaft assembly if

readings do not fall within limits.

Install turbine housing (3) on center

housing (2) and align match marks.

Install V-band coupling (12) on turbine

housing (3) and center housing (2) so

T-bolt end does not interfere with

turbine housing. Apply antiseize

compound to threads on T-bolt and

tighten nut to 160 lb-in (18 N-m).

Loosen to 50 lb-in (5.6 N-m) and

retorque to 152-168 lb-in (17.2-19.0

N-m).

Check shaft radial movement as

follows:

(a)

(b)

Position magnetic base dial indicator

(32) on flat surface of turbine

housing inlet flange.

Insert dial indicator tip extension rod

into oil drain hole with rod touching

shaft and perpendicular.

NOTE

Insure adaptor rod does not

contact sides of center housing or

readings are invalid.

(c) Grasp ends of rotating assembly

and apply equal pressure at each

end, moving rotating shaft toward

and away from dial indicator.

Crosswise movement must be

between 0.003 and 0.007 inch.

C h a n g e 15-101

|

|

|

|

|

Privacy Statement -

Copyright Information. -

Contact Us