| Tweet |

Custom Search

|

|

|

||

TM 9-2815-220-24

THREADED INSERT REPLACEMENT

0030 00

REMOVAL (Continued)

C

6

5

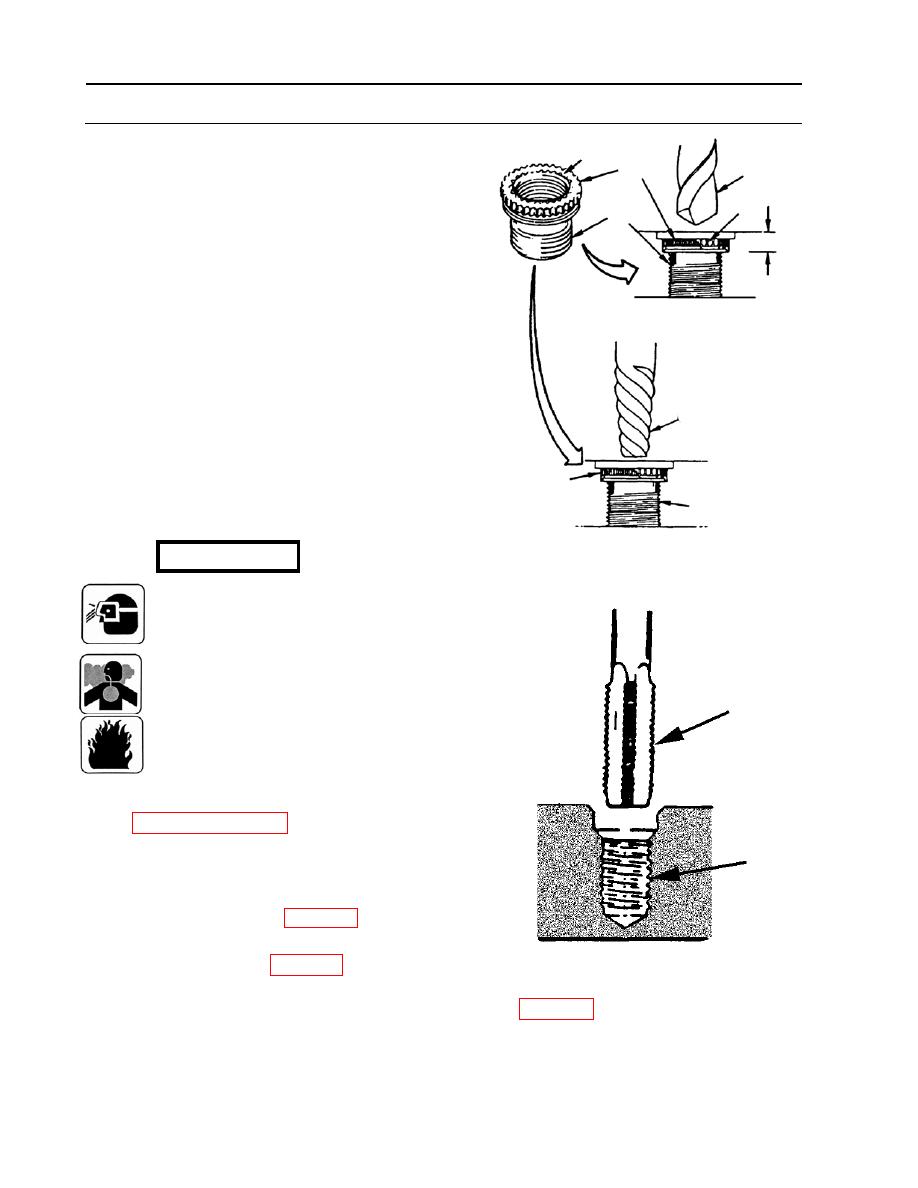

4. Remove lock-ring type insert (4).

A B

a. Using portable electric drill and drill

4

bit (5), drill through lock-ring (6) and

neck (A) of insert (4).

b. Drill to existing counterbore

depth (B).

c. Remove all serration interlocks (C)

on lock-ring (6) and neck of

insert (4).

d. Drive screw extractor (7) through

lock-ring (6) into insert (4).

7

b. Using screw extractor (7), unscrew

insert (4). Lock-ring (6) will be

6

forced out with insert (4).

4

CLEANING

WARNING

Compressed air can injure you

and others. Do not aim air at

personnel. Do not use more than

30 psi. Always wear goggles.

Cleaning solvent is mildly toxic.

Solvent evaporates and both the

9

fumes and liquid are flammable.

See Warning in front of Manual.

1. See Work Package 0028 for Standard

Cleaning Procedures.

8

2. Clean component (8) threads.

a. Lubricate thread cutting tap (9) with

engine oil (item 21, WP 0173).

b. Using tap wrench and thread cutting

tap (9) (item 120, WP 0176), clean

component (8) threads by slowly

c. Flood with cleaning solvent (item 8,

turning tap in and out of component

threads.

blow dirt and any loose metal chips

out of component (8) threads.

WP 0030 00-2

|

||

|

||