| Tweet |

Custom Search

|

|

|

||

TM 9-2815-220-24

THREADED INSERT REPLACEMENT

THIS WORK PACKAGE COVERS:

Removal, Cleaning, Inspection, Repair, and Installation

INITIAL SETUP:

Tools:

Expendable and Durable Items:

Compressed air

Cleaning solvent (item 8, WP 0173)

General mechanic's tool kit (item 121, WP 0176)

Goggles (item 23, WP 0173)

Electric drill, portable (item 34, WP 0176)

Lubricating oil (item 21, WP 0173)

Extractor tool (item 39 or 40, depending on insert

Sealant compound (item 30, WP 0173)

size, WP 0176)

Personnel Required:

Slimsert tool kit (item 122, WP 0176)

Track Vehicle Repairer (1) 63H10

Thread die & tap set (item 120, WP 0176)

To permit higher stresses on studs and bolts that are set in aluminum castings, it is common

practice to install inserts of a stronger metal into which the studs or bolts are threaded.

Helical-coil and screw thread inserts are designated to perform this function. The AVDS-1790

family of engines incorporates helical-coil inserts in many locations as original equipment. If

the hole in which the original insert is installed becomes oversize, a threaded insert may be

used in its place to allow the original size fastener to be used.

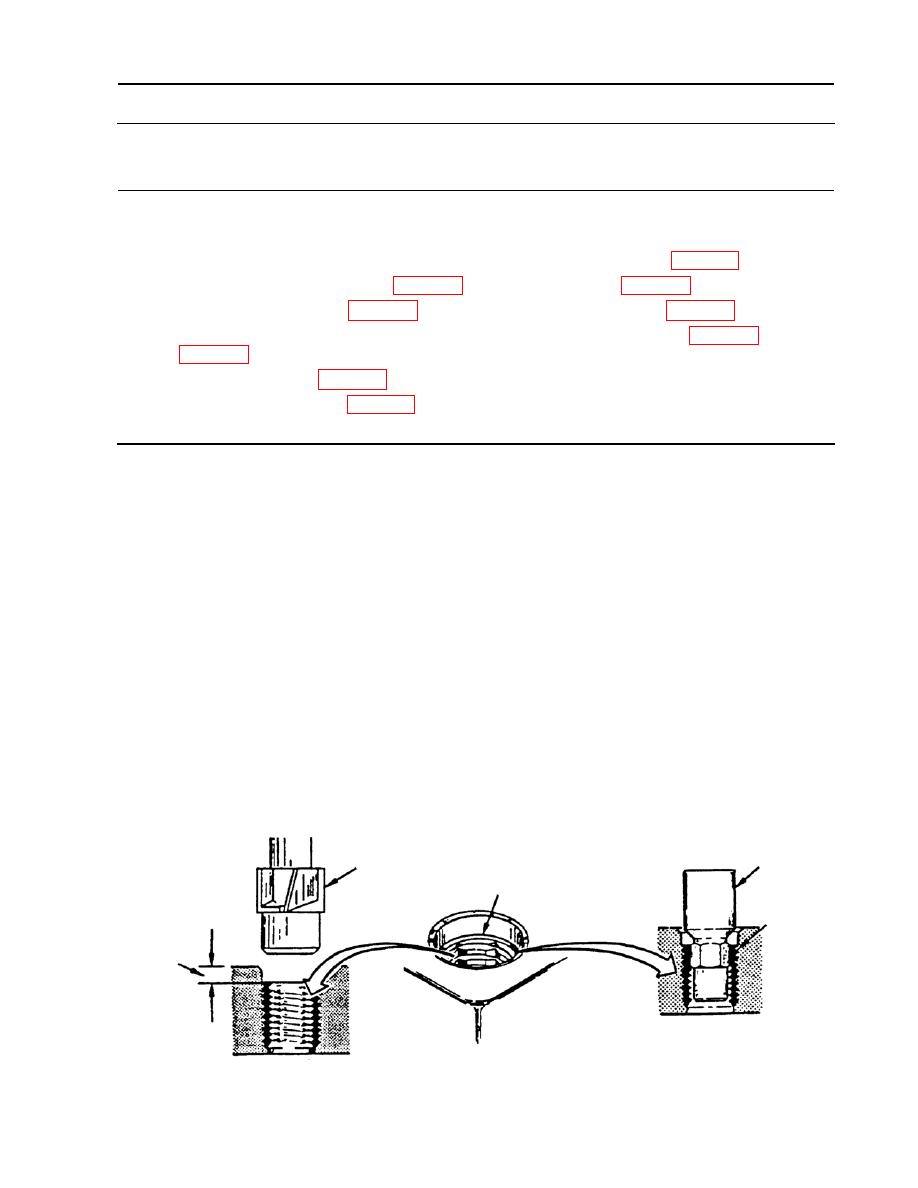

REMOVAL

3. Remove insert (1).

a. Insert drive wrench (3) into insert (1).

1. Verify type of insert.

b. Using ratchet handle and drive

a. If insert is swage type, go to step 2.

wrench, unscrew insert (1).

b. If insert is lock-ring type, go to step 4

c. Go to Cleaning.

2. Removal of swage type insert (1).

a. Using portable electric drill and

extractor tool (2), drill out top of

insert (1) to counterbore depth (A).

3

2

1

1

A

WP 0030 00-1

|

||

|

||