| Tweet |

Custom Search

|

|

|

||

TM 9-2815-220-24

GENERATOR (650 AMPERE) DRIVE GEAR TEST

0039 00

TEST METHOD ONE: DRIVE GEAR INSTALLED ON ENGINE

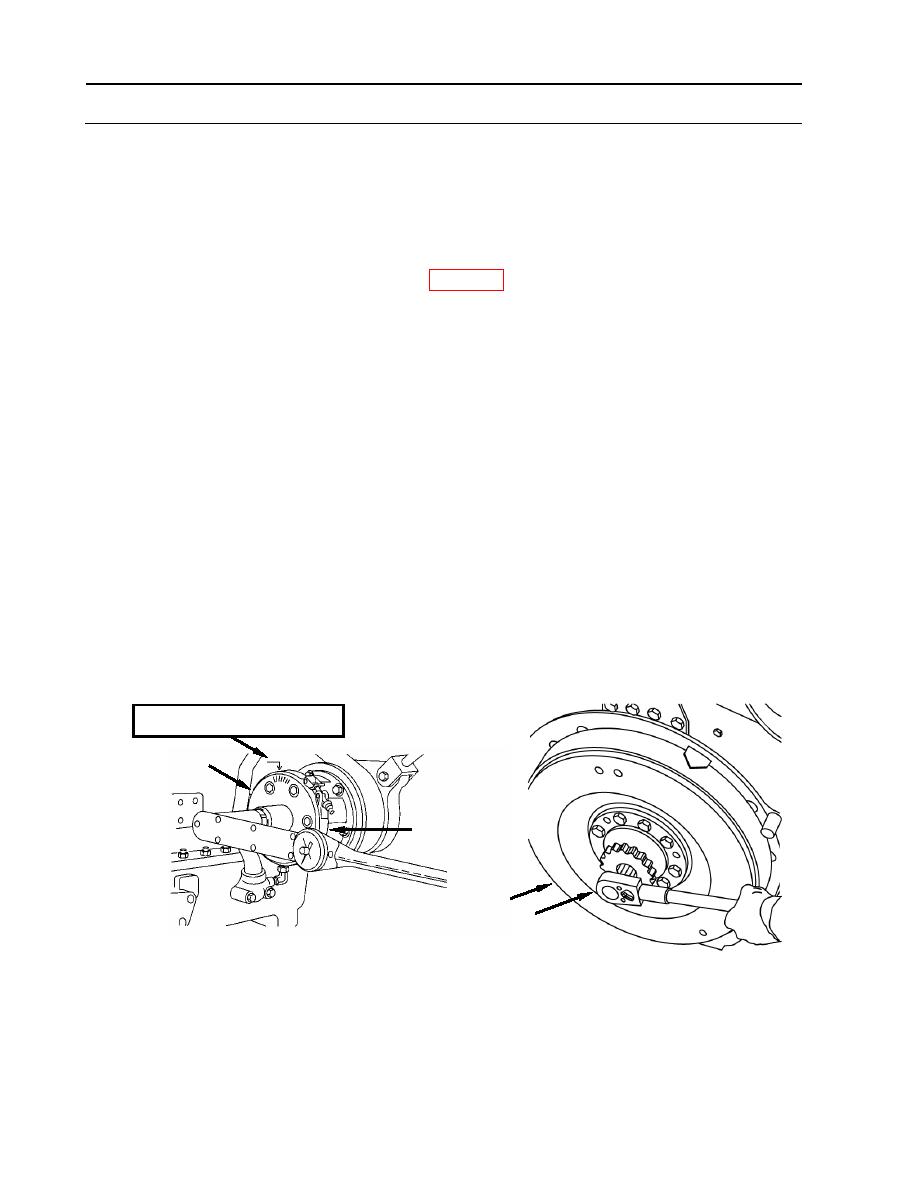

1. Position generator coupling tool (1) on generator end plate (2) and secure with coupling

clamp (3) that was removed with generator.

a. Improvise a pointer and align it with degree markings on generator coupling tool.

2. Prevent crankshaft from rotating.

a. Install engine turning tool (4) (item 136, WP 0176) on flywheel (5) and block so that

crankshaft cannot rotate.

NOTE

A 300 foot-pound (406 Nm) capacity torque wrench is required for

the test.

3. Check drive gear deflection/slippage.

a. While watching indicator on the generator coupling tool (1), remove backlash, then

gradually increase torque to 167 foot-pounds (227 Nm).

b. Check deflection by observing degrees indicated on coupling tool at 167 foot-pounds

(227 Nm) torque. Reading must be between 8 and 17 degrees. If not, coupling is faulty

and must be replaced.

c. Check slippage by removing torque and reading indicator. If indicator returns to zero,

slippage has not occurred and coupling is good. If indicator does not return to zero,

coupling has slipped at too low a torque value and must be replaced.

Pointer and degree marks

1

2, 3

5

4

END OF TEST METHOD ONE

WP 0039 00-2

|

||

|

||