| Tweet |

Custom Search

|

|

|

||

TM 9-2815-220-24

FLYWHEEL AND SPUR GEAR REPLACEMENT (2CA, 2DA)

THIS WORK PACKAGE COVERS:

Removal, Cleaning, Inspection, and Installation

INITIAL SETUP:

Tools:

Personnel Required:

Dial indicator (item 65, WP 0176)

Track Vehicle Repairer (2) 63H10

Eye bolt (item 11, WP 0176)

Equipment Conditions:

General mechanic's tool kit (item 121, WP 0176)

Engine level on flat surface

Splined wrench (engine turning tool) (item 136,

Suitable lifting device

Torque wrench, 500 - 2500 inch/pounds

(item 126, WP 0176)

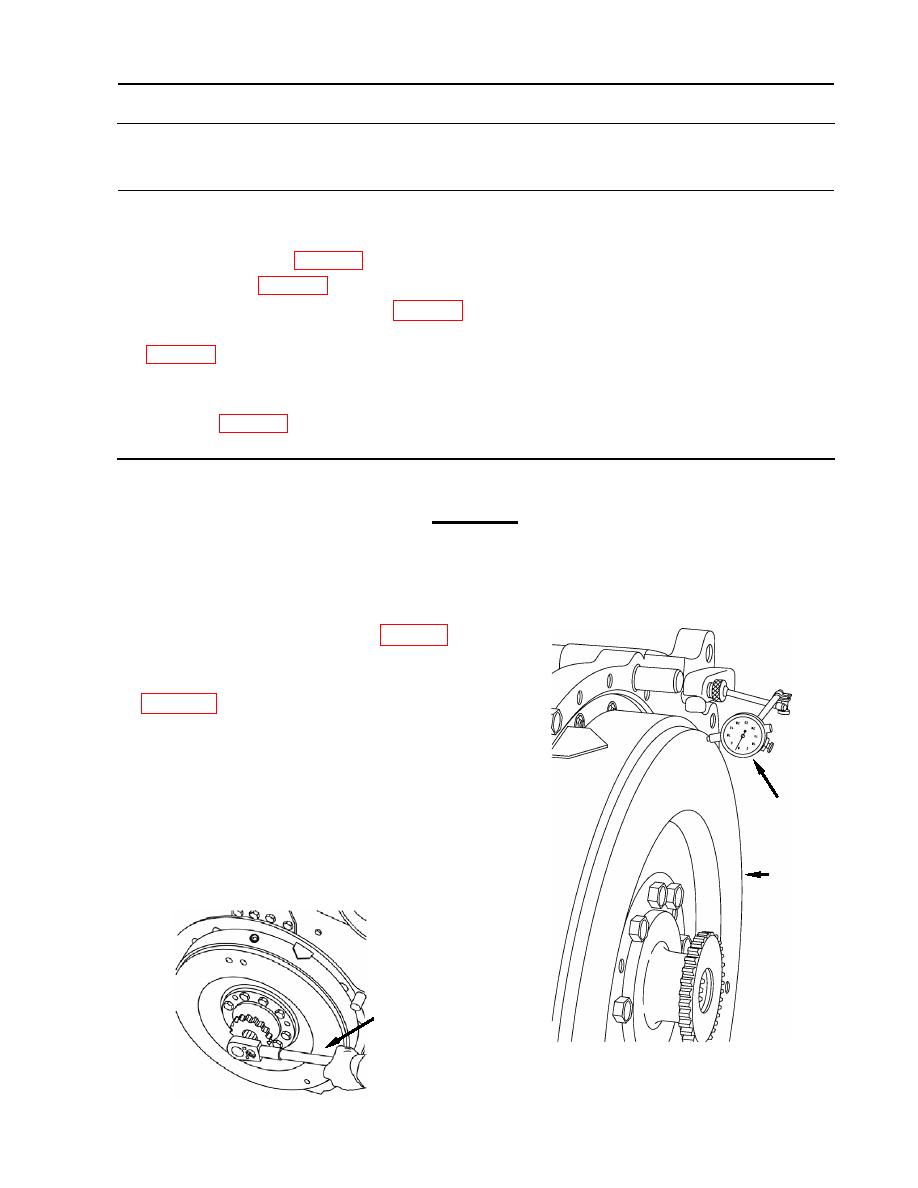

FLYWHEEL RUN-OUT

CAUTION

Flywheel run-out must be checked prior to removal of the old

flywheel and after installation of a new flywheel. The first check is to

determine if the old flywheel is OK, and the second check is to

determine if the new flywheel meets the run-out criteria.

1. Affix dial indicator (1) (item 65, WP0176) as illustrated.

2. Observe dial indicator (1) while rotating

flywheel (2) with turning tool (3) (item 136,

a. Dial indicator must not indicate more

than 0.015-inch of flywheel run-out.

b. If run-out exceeds 0.015-inch, the

flywheel must be replaced.

1

NOTE

Check run-out of crankshaft

2

flange if flywheel run-out exceeds

limits.

3

WP 0102 00-1

|

||

|

||