| Tweet |

Custom Search

|

|

|

||

TM 9-2815-220-24

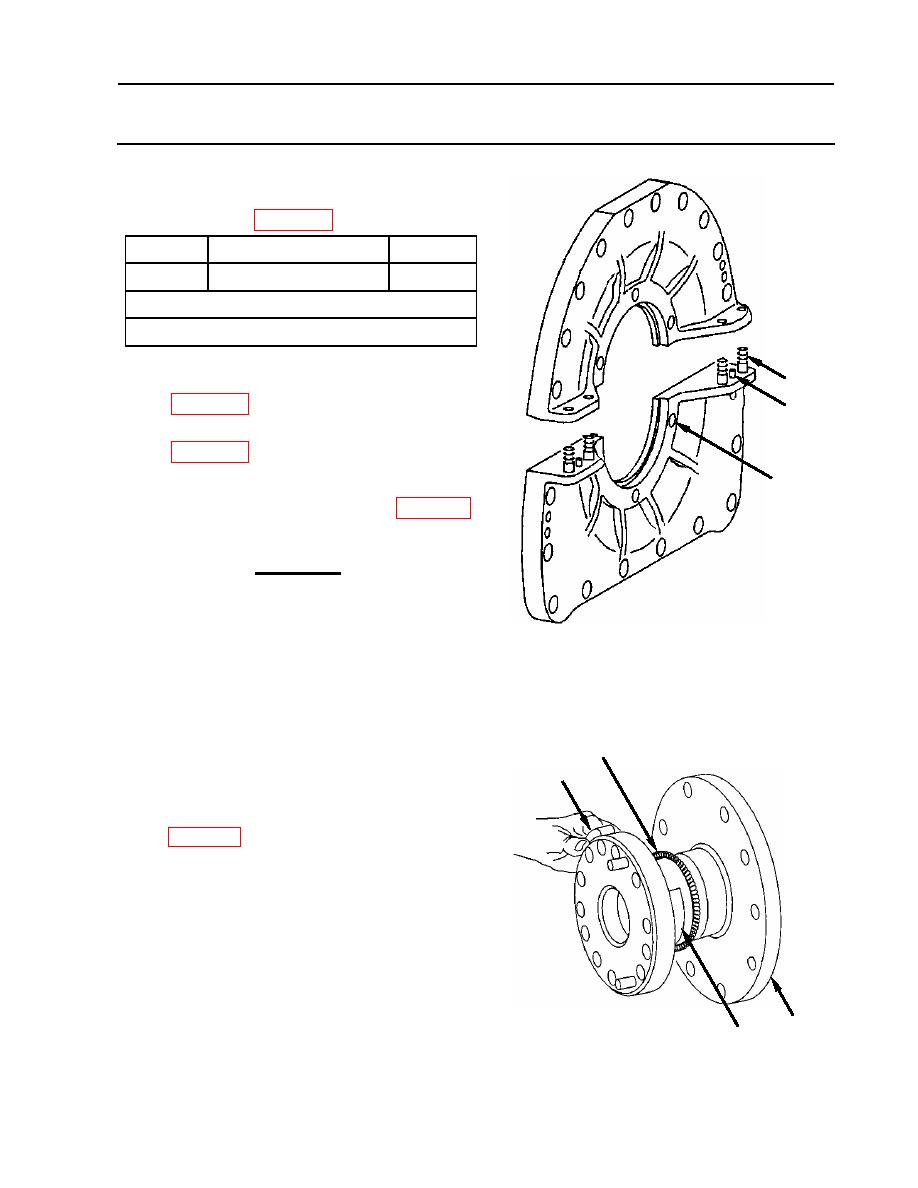

OIL SEAL HOUSING ASSEMBLY AND ASSOCIATED PARTS

REPLACEMENT

0136 00

REPAIR (Continued)

1. Replace bent, stripped, or otherwise damaged

studs (15). See WP 0028.

Callout

Setting Height

Quantity

15

31/31 (24.6062)

4

Stud Dimensions

5/16-18 (51/64) x 5/16-24 (21/32) x 1-5/8

15

2. Replace defective screw thread inserts (16).

See WP 0028.

9,10

3. Replace loose or damaged dowel pins (9,10).

See WP 0028.

INSTALLATION

16

1. Install new oil seal (12) (item 285, WP 0169)

onto crankshaft (13).

CAUTION

One end of seal spring must be turned

2-1/2 turns in relation to the opposite

end for proper engagement. Failure to

comply may lead to crank seal leakage.

a. Install new oil seal spring (14) onto

crankshaft (13). Pre-load spring by

twisting the male end counterclockwise

and the female end clockwise, then insert

14

the male end into the female end and

12

release.

b. Apply silicone compound (item 34,

installing new split oil seal (12).

NOTE

Groove in split oil seal must face

damper end of crankshaft.

c. Install new split oil seal (12) onto

crankshaft (13).

13

d. Position oil seal spring (14) in split oil

12

seal (12) so that splits in each piece are

180 degrees apart.

WP 0136 00-5

|

||

|

||