| Tweet |

Custom Search

|

|

|

||

TM 9-2815-220-24

CRANKSHAFT REPLACE/REPAIR

0139 00

CLEANING

1. See Work Package 0028 for Standard Cleaning Procedures.

WARNING

Compressed air used for cleaning purposes must not exceed 30 psi

(207 kPa). Use only with effective chip guarding and personal

protective equipment (goggles/shield, gloves, etc.). Failure to comply

may result in personal injury.

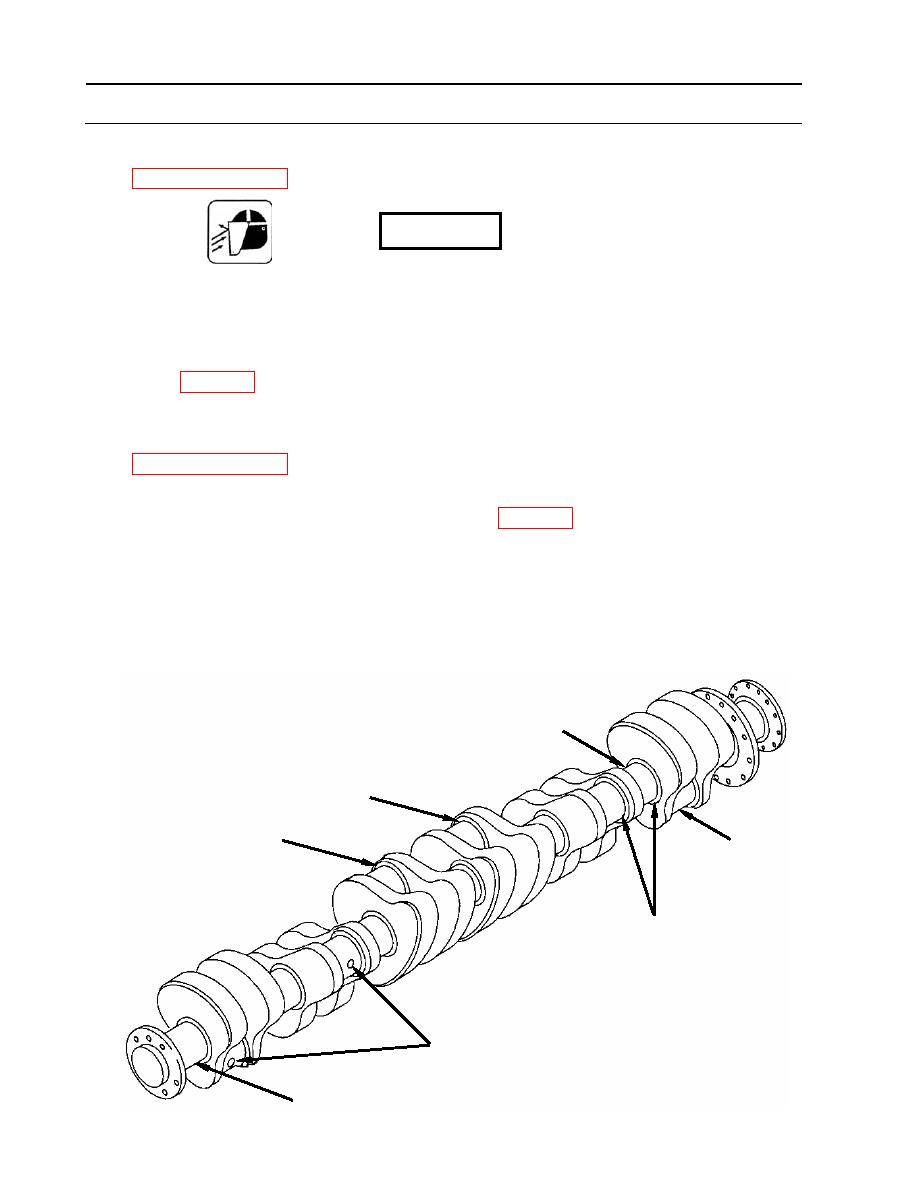

2. Clean crankshaft oil passages (A) with compressed air and brass wire probes

(item 13, WP 0176).

INSPECTION

All parts must be inspected with care. Replace parts if damage or wear exceeds allowable limits.

1. See Work Package 0028 for Standard Inspection Procedures.

2. Visually inspect crankshaft (14).

a. Look for cracks with a magnifying glass (item 73, WP 0176) and a strong light. Pay

particular attention to areas around crankshaft oil holes (A) and fillets (B) adjacent to

crankshaft counter weights. Replace any crankshaft that has cracks.

b. Check connecting rod journal radii (C) of crankshaft for wear or damage. Mark minor

defects for future repair.

c. Check main and connecting rod journals (D) for nicks, burrs, grooves, scratches, galling,

scuffing, or discoloration. Mark minor defect areas for future repair.

D

C

C

D

B

A

D

WP 0139 00-10

|

||

|

||