| Tweet |

Custom Search

|

|

|

||

TM 9-2815-220-24

OIL PUMP REPAIR

THIS WORK PACKAGE COVERS:

Disassembly, Cleaning, Inspection, Repair, and Assembly

INITIAL SETUP:

Tools:

Mandatory Replacement Parts:

Depth micrometer set (item 48, WP 0176)

Ball bearing (item 246, WP 0175)

General mechanic's tool kit (item 121, WP 0176)

Ball bearing (2) (item 291.1, WP 0175)

Inside micrometer caliper set (item 16, WP 0176)

Key washer (item 26, WP 0175)

Machine reamer set (item 92, WP 0176)

Self-locking nut (14) (item 33, WP 0175)

Outside micrometer caliper set

Self-locking nut (item 219, WP 0175)

(item 17, WP 0176)

Spring (item 287.1, WP 0175)

Socket wrench (item 107, WP 0176)

Spring (item 346.1, WP 0175)

Socket wrench adapter (item 3, WP 0176)

Expendable and Durable Items:

Spring tester (item 117, WP 0176)

Lubriplate (item 23, WP 0173)

Telescoping gauge set (item 54, WP 0176)

Lock wire (item 44, WP 0173)

Torque wrench, 0-300 inch-pounds

Personnel Requirements:

(item 124, WP 0176)

Track Vehicle Repairer (1) 63H10

Torque wrench, 0-175 foot-pounds

(item 127, WP 0176)

Equipment Conditions:

Fabricated Item:

Engine on maintenance stand (WP 0130)

Modified socket (item 12, WP 0177)

Oil pump removed (WP 0153)

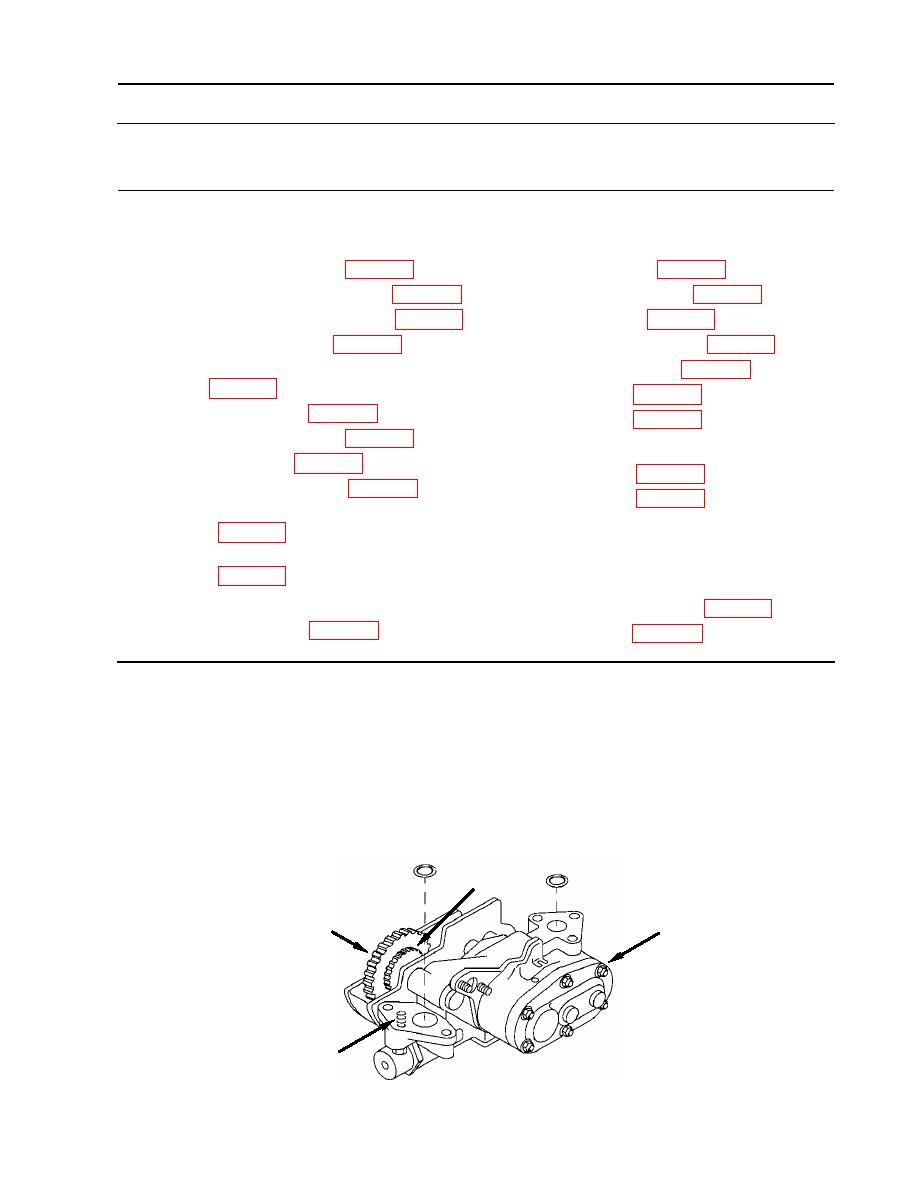

DISASSEMBLY

There are two oil pump assemblies in use and they are interchangeable. The major difference

is the drive gears: on the newer model (12468945) the spur gear to cluster gear ratio provides a

higher operating speed of the pump. This higher speed increases oil flow capability. If you

have the older pump (11683982), it is acceptable for use, but is not supported in the RPSTL

nor in the repair manual. You can identify which pump you have by counting teeth (A) on the

smaller gear circle of the cluster gear. The high-speed pump has 26 teeth and the older low-

speed pump has 24.

A

Oil Pump

Cluster Gear

Assembly

Captive Screw

WP 0154 00-1

|

||

|

||