TM 9-2815-225-34&P

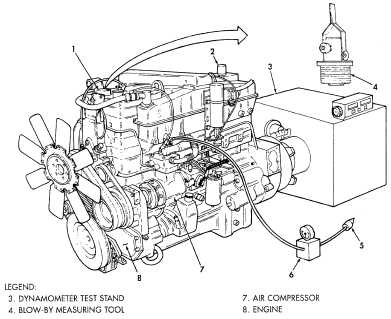

3-92. ENGINE DYNAMOMETER TESTING (Contd)

LOCATION/ITEM

ACTION

REMARKS

c. Power Check

CAUTION

Do not shut engine down immediately after power check is complete. Serious engine

damage will result.

8.

Engine (8)

a. Run at 2100 rpm for 4 minutes.

Refer to power check in test chart.

Check crankcase pressure with

blow-by measuring tool (4). Repeat

procedure until engine (8)

develops 96-100% rated

horsepower at standard fuel rate

within permissible crankcase

pressure limit. Operate air

compressor (7) in non-pumping mode.

NOTE

At each phase, record crankcase pressure (blow-by), engine speed, and load at one-minute

intervals. Watch for increases or wide shifts in blow-by pressure. If sudden increase

happens, or if it is more than 12" H2O, do the preceding test over again and run engine 15

more minutes. When blow-by is OK, do next test. If not OK, stop the test and find reason

for too much blow-by. Check engine for fuel, oil, water, air, or exhaust leaks after each test

and fix as needed.

Phase 1 - 25% HP @1200 RPM @160° water temperature.

Phase 2 - 40% HP @1200 RPM

Phase 3 - 65% HP @1600 RPM

Phase 4 - 100% HP @ Nominal torque peak RPM *(1200) RPM

Power Check - 96-100% HP @1600 RPM

*100 RPM below torque peak RPM

Table 3-1. Dynamometer Test Chart

ENGINE

HP @ RPM

RATED

HP @ RPM

500 FT-ALT

FUEL

RATE

LB/HR

AIR

MANIFOLD

PRESSURE

IN/HG

ALTITUDE

MAX. HP

ALT.

CRANKCASE

PRESSURE

W/TURBO

T46B

PHASE 1

TO 160°F

HP @ RPM

PHASE 2

2 MIN.

HP @ RPM

PHASE 3

5 MIN.

HP @

RPM

PHASE 4

4 MIN.

HP @

RPM

POWER

CHECK

4 MIN.

HP @ RPM

NTC

400

400 @

2100

400 @ 2100

139-145

39/47

12,000

12”H2O

100 @

1200

160 @1200

260

@1600

Full Load

@1200

384 @

2100

3-687

|

|