| Tweet |

Custom Search

|

|

|

||

TM 9-2815-226-34-1

(13) Apply pressure to contact plate to firmly position contact pins against counterbore inside diameter.

(14) Record indicator reading.

(15) Move gage 90 degrees and repeat procedure.

(16) Move gage 180 degrees and repeat procedure.

(17) Compare readings. Maximum out-of-alinement is 0.005 in. (0.127 mm) total indicator reading.

(18) If out-of-alinement exceeds specification, a replacement sleeve must be installed (para 3-9f).

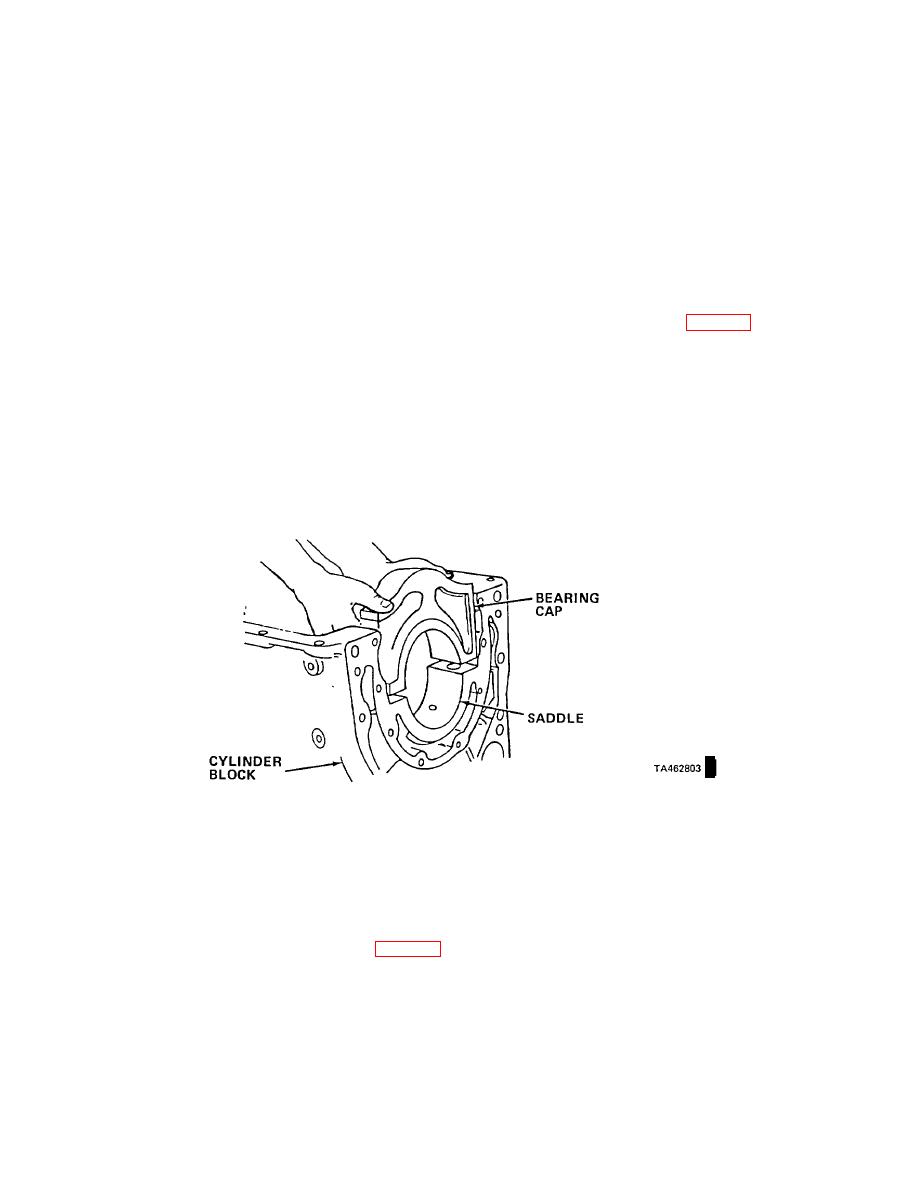

l. Check main bearing caps.

NOTE

Main bearing caps on 1980 and 1982 models have 1 in. diameter bolts with a lock

plate; 1984 models have 3/4 in. bolts with washers.

Bearing cap positions are marked on caps.

(1) Reinstall and seat main bearing caps on their respective saddles.

(2) Check for cap movement.

NOTE

Replacement No. 7 bearing cap is provided without dowel pin holes. Dowel pin

holes must be drilled into cap (para 3-9).

(3) Discard loose caps.

3-66 Change 1

|

||

|

||