| Tweet |

Custom Search

|

|

|

||

TM 9-2815-226-34-2

Table 3-6. Valve Setting Specifications

OIL

Intake

TEMPERATURE

Inch (mm)

Inch (mm)

COLD

0.011

0.023

(0.28)

(0.58)

HOT

0.008

0.023

(0.20)

(0.58)

(10)

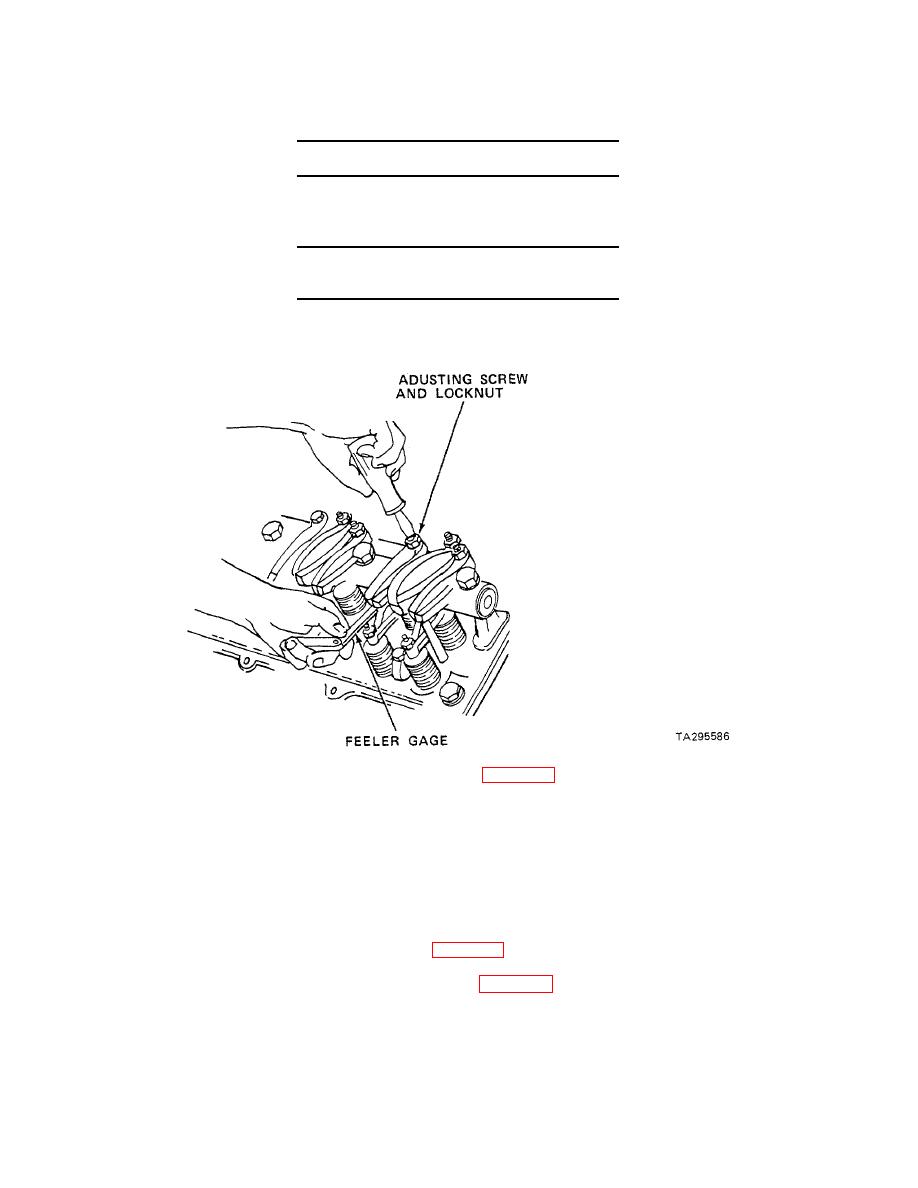

Determine whether valve is intake or exhaust. Exhaust valve crossheads are wider at rocker

lever contact point.

(11)

Insert appropriate thickness feeler gage (Table 3-6) between rocker lever and crosshead.

(12)

Turn adjusting screw down until lever just touches gage.

(13)

Using ST-669 torque wrench adapter with screwdriver bit and deep socket, hold adjusting screw

and torque locknut to 35 - 40 ft lbs (47 - 54 Nm).

(14)

If ST-669 not used, hold adjusting screw with screwdriver and torque locknut to 40 - 45 ft lbs (54 -

61 Nm).

(15)

Adjust adjacent valve referring to Table 3-6 for proper valve clearance.

(16)

Rotate engine to next pulley position (Table 3-5) and so on until all injectors and valves are

adjusted.

3-456

|

||

|

||