TM 9--2815--247--34

0036 00--13

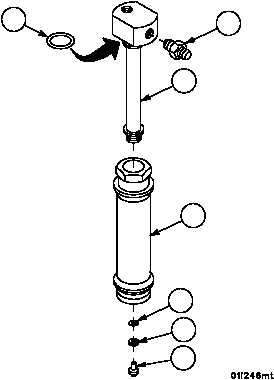

FUEL INJECTOR NOZZLE AND HOLDER REPAIR -- CONTINUED

0036 00

Assembly

NOTE

During assembly, the addition or removal of spring adjust-

ing shims (to obtain the correct gauge pressure reading

on the nozzle tester) may require various shim combina-

tions available in the shim sets. Although each nozzle

assembly pressure reading may vary, experience will indi-

cate the approximate shim(s) thickness required to make

up pressure differences. The nozzle assembly must be

completely assembled, torque tightened and checked

again on the nozzle tester to assure proper spacer com-

bination and pressure reading. This procedure may have

to be repeated several times before achieving a satisfac-

tory reading.

1. Install fuel inlet stud (5) into body (6) and torque to 70--75 lb--ft (94.92--101.70 NSm).

2. Clamp body (6) in soft--jawed vise.

3. Install a new preformed packing (32) and retainer (2) on body (6).

4. Install spacer ring (31), shims (30), and fuel injector nozzle and holder seat (29) on body (6).

Figure 34

5

6

29

30

31

2

32

|

|