TM 9--2815--247--34

0064 00--17

ENGINE CRANKSHAFT REPAIR -- CONTINUED

0064 00

Installation -- Continued

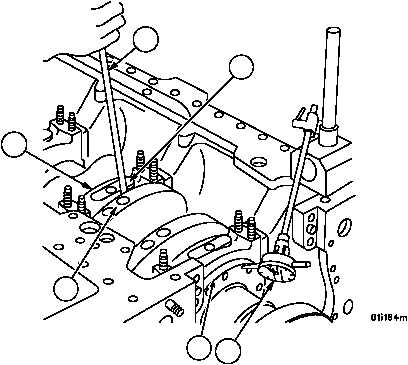

12. Mount a dial indicator (42) on block so indicator point contacts drive gear flange (39) on crankshaft (14).

13. Using a heavy screwdriver (44), wedge between main bearing cap (9) and crankshaft (14) counterweight, push

crankshaft toward front end.

14. Set indicator (42) on zero reading (“0”).

15. Using a heavy screwdriver (44), push crankshaft toward the rear of block and check indicator end play reading.

End play should be from 0.007 to 0.019 inch (0.1778 -- 0.4826 mm).

Figure 2

44

14

42

9

14

39

|

|