|

|

|

|

|

TM 9--2815--247--34

0070 00--7

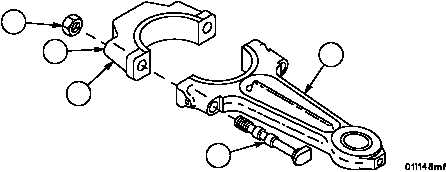

CONNECTING ROD ASSEMBLY AND ASSOCIATED PARTS REPAIR --

CONTINUED

0070 00

Inspection -- Continued

11. Apply lubricant to rod bolt threads (13) and nut seat (15).

12. Assemble rod (3) and cap (2), and torque tighten both nuts (1) alternately to 100--150 lb--in (11.3--16.95 NSm);

then to 50--54 lb--ft (67.8--73 NSm); then to 105--108.5 lb--ft (141--146 NSm); then to a final torque of 150--154

lb--ft (203.4--209 NSm).

Figure 8

1

15

2

3

13

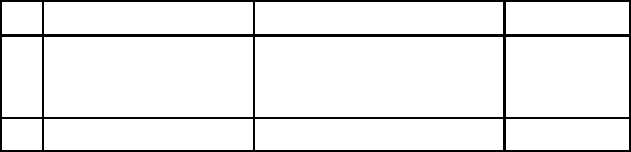

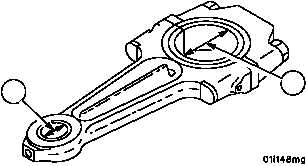

13. Measure inside diameter (16) of rod bearings. Replace bearings that do not meet the following limits.

14. Measure inside diameter (17) of piston pin sleeve bushing. Replace bushings that do not meet the following lim-

its.

REF

NO.

POINT OF MEASUREMENT

SIZES AND FITS OF NEW PARTS

inches (mm)

WEAR LIMITS

16

Inside diameter of bearing at

proper torque tightness

standard

0.003 (0.0762 mm) undersize

0.010 (0.254 mm) undersize

3.7546 (95.36684)

3.7516 (95.29064)

3.7446 (95.11284)

3.7568 (95.42272)

3.7638 (95.60052)

3.7468 (95.16872)

3.7573 (95.43542)

3.7543 (95.35922)

3.7473 (95.18142)

17

Inside diameter of bushing type

sleeve bearing

2.1275 (54.0385)

2.1277 (54.04358)

2.1248 (53.96992)

Figure 8

16

17

|

|

|

|

|

Privacy Statement -

Copyright Information. -

Contact Us