ARMY TM 9-2815-255-24

AIR FORCE TO 38G1-95-2

MARINE CORPS TM 2815-24/4

f.

Set No. 1 piston at TDC compression stroke and install timing pin (JDE81-4) in flywheel, refer to FIGURE 3-97.

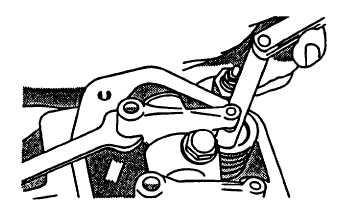

FIGURE 3-95. Adjusting Valve Clearance

g.

Adjust valve clearance on No. 1 and 3 exhaust valves and No. 1 and 2 intake valves, refer to FIGURE 3-96.

h.

Turn crankshaft 360 degrees so that No. 4 piston is at TDC compression stroke and reinsert timing pin.

i.

Adjust valve clearance on No. 2 and 4 exhaust valves and No. 3 and 4 intake valves.

FIGURE 3-96. Checking Valve Clearance

3-32.2. Measure Valve Lift.

Measuring valve lift can give an indication of excess wear on cam lobes, followers, and/or pushrods.

CAUTION

For a more accurate measurement, it is recommended that valve lift be measured at 0.00 inch

(0.00 mm) rocker arm-to-valve tip clearance.

a.

Remove valve cover, refer to paragraph 3-31.1.

b.

Using center bolt on harmonic balancer, rotate crankshaft clockwise and observe No. 1 pushrods. When both

pushrods can be rotated freely engine is on compression stroke. Continue to rotate engine until timing pin

(JDE81-4) can be installed in flywheel, refer to FIGURE 3-97.

3-131

|

|