ARMY TM 9-2815-255-24

AIR FORCE TO 38G1-95-2

MARINE CORPS TM 2815-24/4

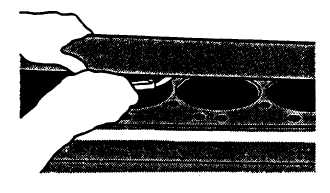

FIGURE 3-141. Measuring Cylinder Block Top Deck Flatness

CAUTION

When cylinder block Is machined (top deck or crankshaft bearing bores), the dimension from

centerline of crankshaft bearing bore to top deck will be changed. Make sure that this dimension

will not be less than 11.889 Inches (301.98 mm). Otherwise, piston may contact cylinder head.

CAUTION

If cylinder block top deck is resurfaced, also measure depth of liner counter bores. Bore depth

must be within 0.234 to 0.236 Inch (5.95 to 5.99 mm).

d.

Measure cylinder liner height as follows:

NOTE

If liner height was not checked when liners were removed, refer to paragraph 334.6., step e, or a

new liner is being installed in a new or used cylinder block, liner height must be checked.

(1)

Be sure liner bore in cylinder block is clean.

(2)

Install liners without -rings and packing.

CAUTION

Liner should rotate smoothly by hand when Installed. If remove liner and polish bottom liner

pilot bore in cylinder block with emery cloth. Use a shop towel or other suitable means to collect

debris when polishing bore.

(3)

Install liner with its mark toward the front of the engine. Secure with capscrews and washers. Tighten

screws to 50 ft-lbs (68 Nm).

(4)

Using gage (JDG451) and dial indicator, measure each liner height in four places, at approximately 1, 5, 7,

and 11 o'clock positions as viewed from the rear of the engine (flywheel end). Record all measurements.

(5)

Liner height specification is 0.0004 to 0.004 inch (0.01 to 0.10 mm). Maximum permissible difference

between readings within one cylinder or between adjacent cylinders is 0.002 inch (0.06 mm).

3-201

|

|