TM 9-2920-243-34

NOTE

operation normally performed after

The armature used in this starter is a

resurfacing is not required.

flush mica design and the undercutting

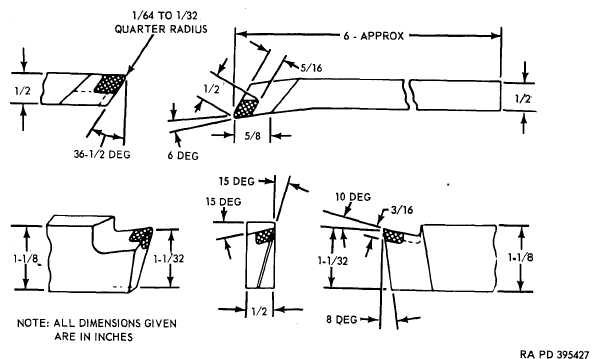

Figure 3-32. Cutting tool sharpening dimensions.

(2) Polishing commutator. Remove all copper

and mica particles with compressed air. Polish

commutator in a lathe with 2/0 sandpaper as

illustrated in figure 3-34, with armature rotating

at 1500 rpm.

(3) Checking armature eccentricity. Set up a

dial indicator gage and measure the runout of the

commutator (fig. 3-28). Total runout should not

exceed 0.003-inch.

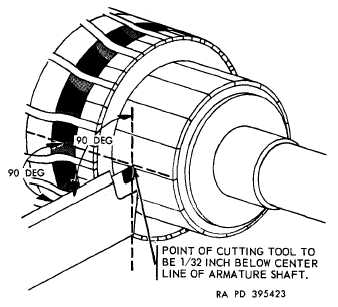

Figure 3-33. Proper position of cutting tool.

3-14

|

|