| Tweet |

Custom Search

|

|

|

||

TM 9-8000

e. Advantage and Usage. The two-stroke cycle

(2) The fuel and air mixture is compressed to

about one-twentieth of its original volume in a diesel

engine is used almost exclusively in very small

engine. In contrast, the fuel and air mixture in a gasoline

equipment. It is lightweight and able to run at very high

engine is compressed to about one- eighth of its original

speeds due to the absence of a mechanical valve train.

volume. The diesel engine must compress the mixture

this tightly to generate enough heat to ignite the fuel and

2-13. Gasoline Engine Versus Diesel Engine.

air mixture. The contrast between the two engines is

shown in figure2-16.

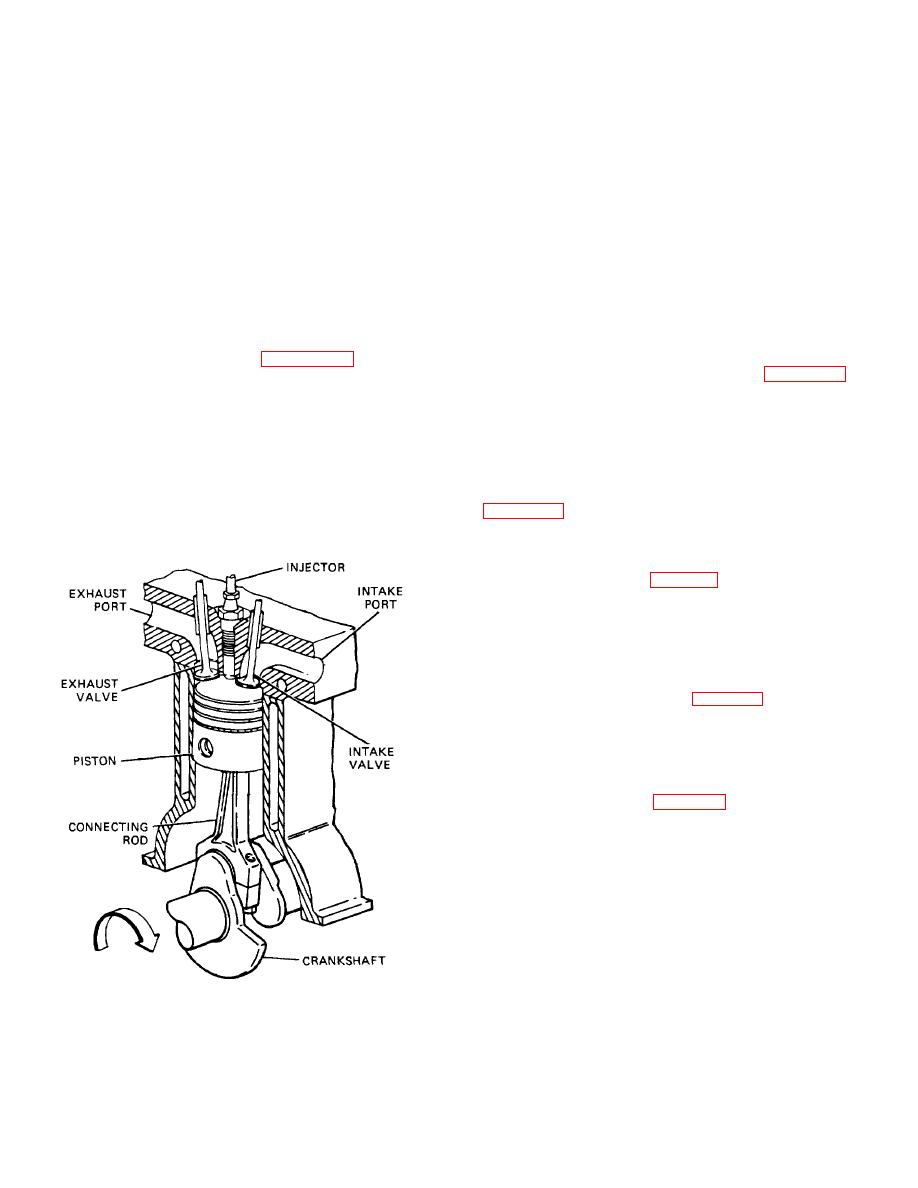

a. General. In many respects, the four- stroke

cycle gasoline engine and the four-stroke cycle diesel

(3) The gasoline engine mixes the fuel and air

engine are very similar. They both follow an operating

before it reaches the combustion chamber. A diesel

cycle that consists of intake, compression, power, and

engine takes in only air through the intake port. Fuel is

exhaust strokes. They also share in the same system for

put into the combustion chamber directly through an

intake and exhaust valves. The component parts of a

injection system. The air and fuel then mix in the

diesel engine are shown in figure 2-15. The main

combustion chamber. This is illustrated in figure 2-17.

differences between gasoline engines and diesel engines

follow.

(4) The engine speed and the power output of

a diesel engine are controlled by the quantity of fuel

(1) The fuel and air mixture is ignited by the

admitted to the combustion chamber. The amount of air

heat generated by the compression stroke in a diesel

is constant. This contrasts with the gasoline engine

engine versus the use of a spark ignition system on a

where the speed and power output are regulated by

gasoline engine. The diesel engine needs no ignition

limiting the air entering the engine. This is illustrated in

system. For this reason, the gasoline engine is referred

to as a spark ignition engine and a diesel engine is

referred to as a compression ignition engine.

b. Operation.

(1) Intake (A, Fig. 2-19). The piston is at top

dead center at the beginning of the intake stroke. As the

piston moves downward, the intake valve opens. The

downward movement of the piston draws air into the

cylinder. As the piston reaches bottom dead center, the

intake valve closes. The intake stroke ends here.

(2) Compression (B, Fig. 2-19). The piston is

at bottom dead center at the beginning of the

compression stroke.

The piston moves up- ward,

compressing the air. As the piston reaches top dead

center, the compression stroke ends.

(3) Power (C, Fig. 2-19). The piston begins

the power stroke at top dead center. Air is compressed

in the upper cylinder at this time to as much as 500 psi

(3448 kPa). The tremendous pressure in the upper

cylinder brings the temper- ature of the compressed air to

approximately 10000F (5380C).

The power stroke

begins with the injection of a fuel charge into the engine.

The heat of compression ignites the fuel as it is injected.

The expanding force of the burning gases pushes the

piston downward, providing power to the crankshaft. The

power generated in a

Figure 2-15. The Four-Stroke Cycle Diesel

TA233318

2-10

|

||

|

||