| Tweet |

Custom Search

|

|

|

||

TM 9-8000

CHAPTER 3

CONVENTIONAL ENGINE CONSTRUCTION

Section I.

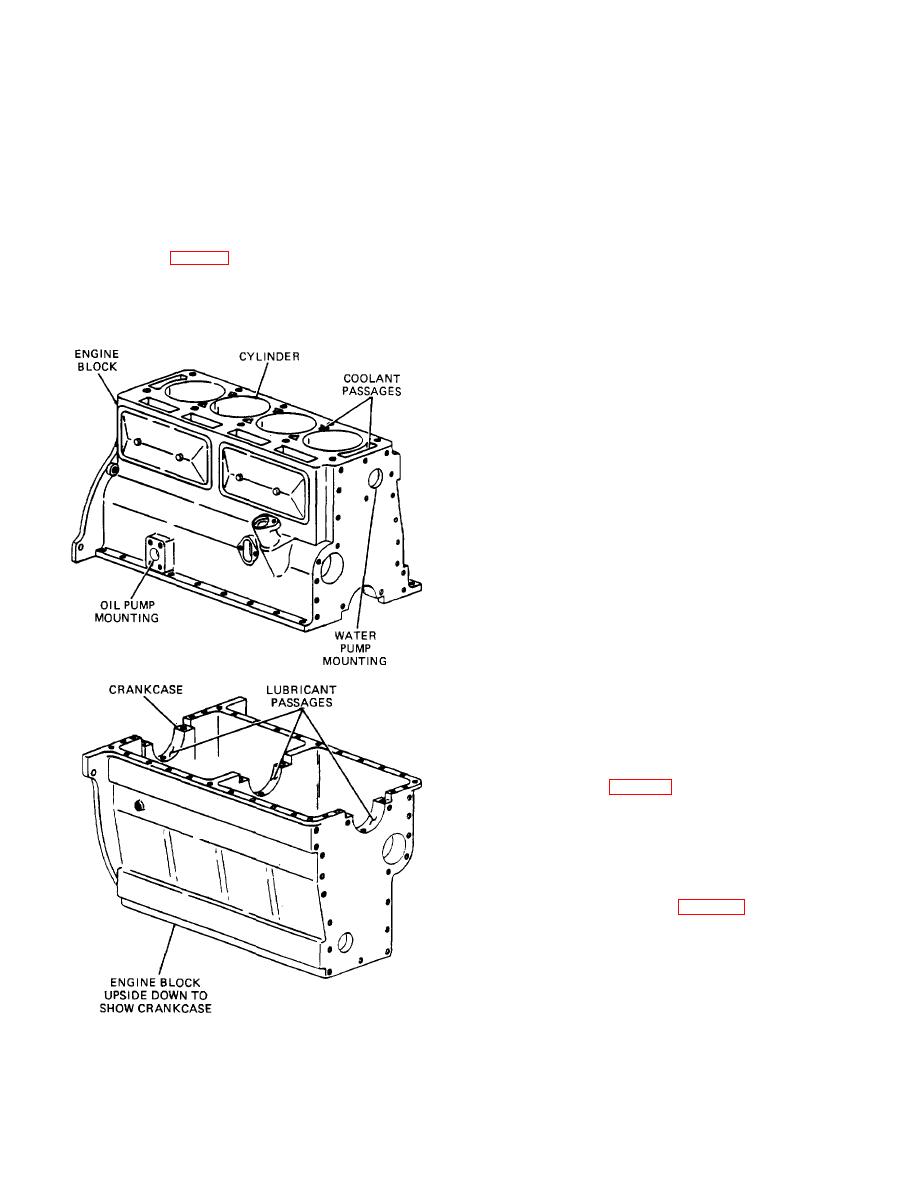

CYLINDER BLOCKS, HEADS, AND CRANKCASES

contains the crankcase, cylinders, coolant pas-

3-1.

Cylinder Blocks - Liquid-Cooled Engines.

sages, and, in the case of flathead engines, the

valve seats, ports, and guides.

a. General (Fig. 3-1). The cylinder, or the

engine block, is the basic foundation of virtually

b. Construction. The cylinder block is a one-

all liquid-cooled engines. The block is a solid

piece casting that is usually an iron alloy con-

casting made of cast iron or aluminum that

taining nickel and molybdenum. This is the best

overall material for cylinder blocks. It provides

excellent wearing qualities, low material and

production costs, and it only changes dimensions

minimally when heated. Another material that is

used for cylinder blocks, although not exten-

sively, is aluminum. Aluminum is used whenever

weight is a consideration. It is not as practical to

use for the following reasons:

(1)

Aluminum is more expensive than cast

iron.

(2)

Aluminum is not as strong as cast iron.

(3) Due to the softness of aluminum, it

cannot be used on any surface of the block that is

subject to wear. This necessitates the pressing,

or casting, of steel sleeves into the cylinder

bores. Threaded holes must be deeper, which

introduces extra design considerations. All of

these things increase production costs.

(4) Aluminum has a much higher expansion

rate than iron when heated. This creates prob-

lems with maintaining tolerances.

c. Cylinders (Fig. 3-2). The cylinders are

bored right into the block. A good cylinder must be

round, not varying in diameter by more than

approximately 0.0005 in. (0.012 mm). The

diameter of the cylinder also must be uniform for

its entire length.

d. Cylinder Sleeves (Fig. 3-3). Cylinder

sleeves or liners commonly are used to provide a

wearing surface other than the cylinder block for

the pistons to ride against. This is important for

the following reasons:

(1) Alloys of steel can be used that will wear

longer than the surfaces of the cylinder block.

TA233351

Figure 3-1. Liquid Cooled Cylinder Block.

3-1

|

||

|

||