| Tweet |

Custom Search

|

|

|

||

TM 9-8000

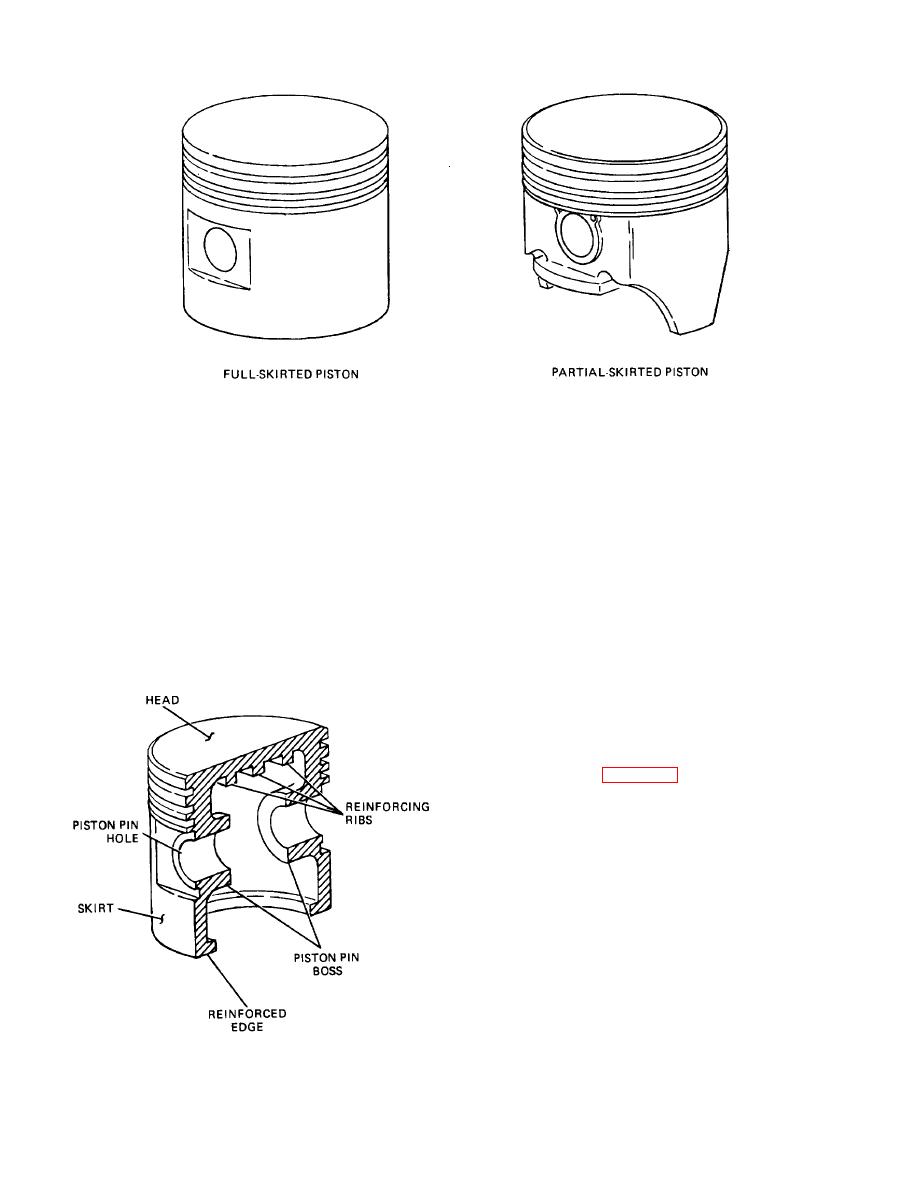

Figure 3-15. Full and Partial-Skirted Pistons.

critical factors. Two of the ways pistons are made

hardness. The following are the most common

strong and light are as follows:

processes for treatment of aluminum pistons.

(1) The head of the piston is made as thin as

(1) The piston is coated with tin so that it will

Is practical. To keep it strong enough, there are

work into the cylinder walls as the engine is broken

ribs cast into the underside of it.

In. This process results in a more perfect fit,

shortening of the break-in period, and an In-

(2) The areas around the piston pin are

crease in overall engine longevity.

reinforced. These areas are called the pin

bosses.

(2) The piston is anodized to produce a

harder outside surface. Anodizing is a process

h. Coatings. Pistons that are made from

that produces a coating on the surface by

electrolysis. The process hardens the surface of

aluminum usually are treated on their outer sur-

the piston. This helps it resist picking up particles

faces to aid in engine break-in and increase

that may become embedded in the piston, caus-

ing cylinder wall damage.

3-6.

Piston Rings.

a. General (Fig. 3-17). Piston rings serve

three Important functions:

(1) They provide a seal between the piston

and the cylinder wall to keep the force of the

exploding gases from leaking into the crankcase

from the combustion chamber. This leakage Is

referred to as blowby. Blowby is detrimental to

engine performance because the force of the

exploding gases will merely bypass the piston

rather than push it down. It also contaminates the

lubricating oil.

(2) They keep the lubricating oil from by-

passing the piston and getting Into the combustion

chamber from the crankcase.

TA233360

Figure 3-16. Piston Structure.

3-10

|

||

|

||