| Tweet |

Custom Search

|

|

|

||

TM 9-8000

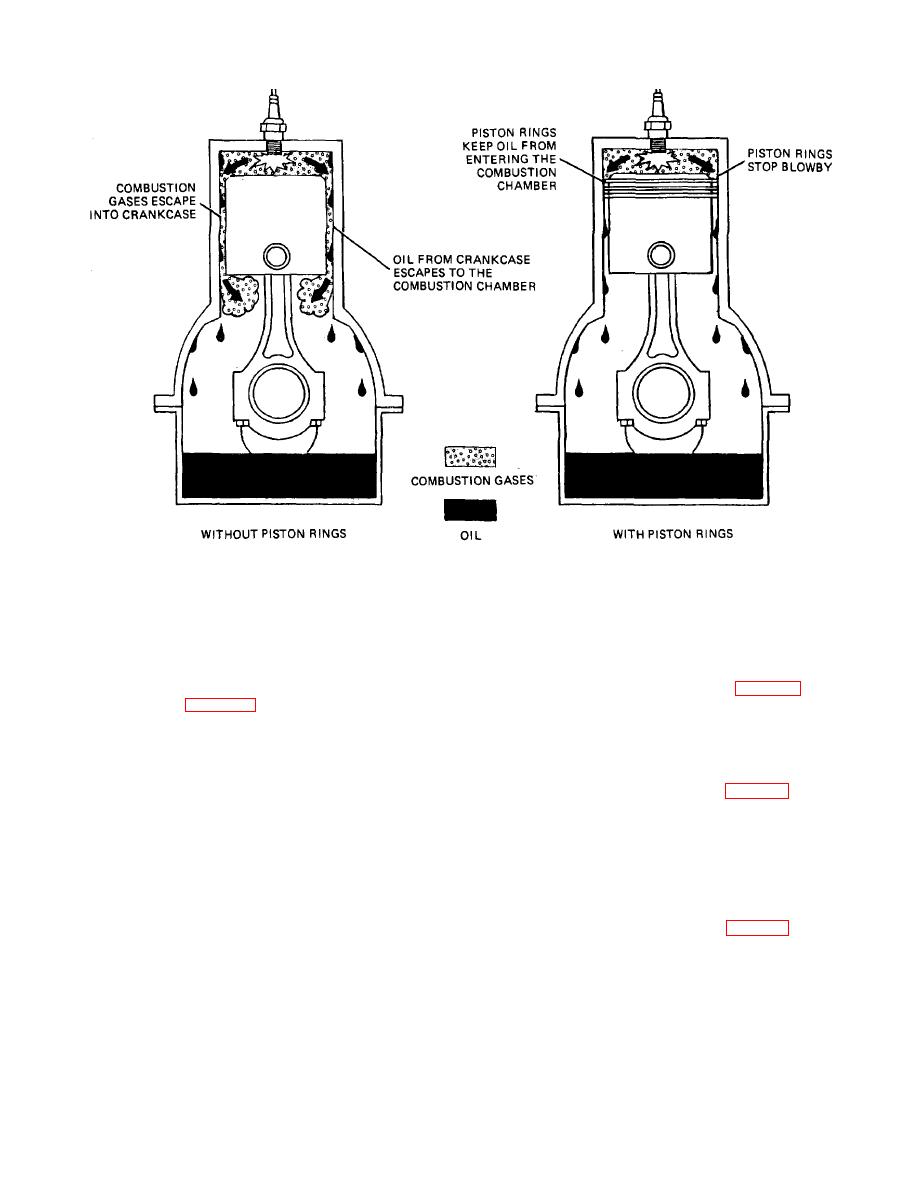

Figure 3-17. Purpose of Piston Rings.

c. Configurations. Piston rings are arranged

(3)They provide a solid bridge to conduct

the heat from the piston to the cylinder wall. About

on the pistons in three basic configurations. They

one-third of the heat absorbed by the piston

are:

passes to the cylinder wall through the piston

rings.

(1) The three-ring piston (A, fig. 3-19)

b. Description (Fig. 3-18). Piston rings are

that has two compression rings from the top,

secured on the pistons by fitting Into grooves.

followed by one oil control ring. This is the most

They are split to allow for installation and expan-

common piston ring configuration.

sion, and they exert an outward pressure on the

cylinder wall when installed. They fit into grooves

that are cut into the piston, and are allowed to float

(2) The four-ring piston (B, fig. 3-19) that

freely in these grooves. A properly formed piston

has three compression rings from the top,

ring, working in a cylinder that is within limits for

followed by one oil control ring. This configura-

tion is common in diesel engines because they are

roundness and size, will exert an even pressure

and a solid contact with the cylinder wall around its

more prone to blowby. This is due to the much

entire circumference. There are two basic clas-

higher pressures generated during the power

sifications of piston rings.

stroke.

(1) The Compression Ring. The compres-

sion ring seals the force of the exploding mixture

has two compression rings from the top, followed

into the combustion chamber.

by two oil control rings. The bottom oil control ring

may be located above or below the piston pin. This

(2) The Oil Control Ring. The oil control

is not a very common configuration in current

ring keeps the engine's lubricating oil from get-

engine design.

ting Into the combustion chamber.

TA233361

3-11

|

||

|

||