| Tweet |

Custom Search

|

|

|

||

TM 9-8000

to provide the desired wearing qualities. At the same

time, the piston pin must not be brittle. To satisfy the

overall requirements of a piston pin, it was found that

c.

a casehardened steel pin is best. Casehardening is a

process that hardens the surface of the steel to any

desired depth. The pin is also made hollow to reduce the

overall weight of the reciprocating mass.

c. Configurations. The following are the

bushing.

(2) A semifloating pin (B, fig. 3-32) is locked to the

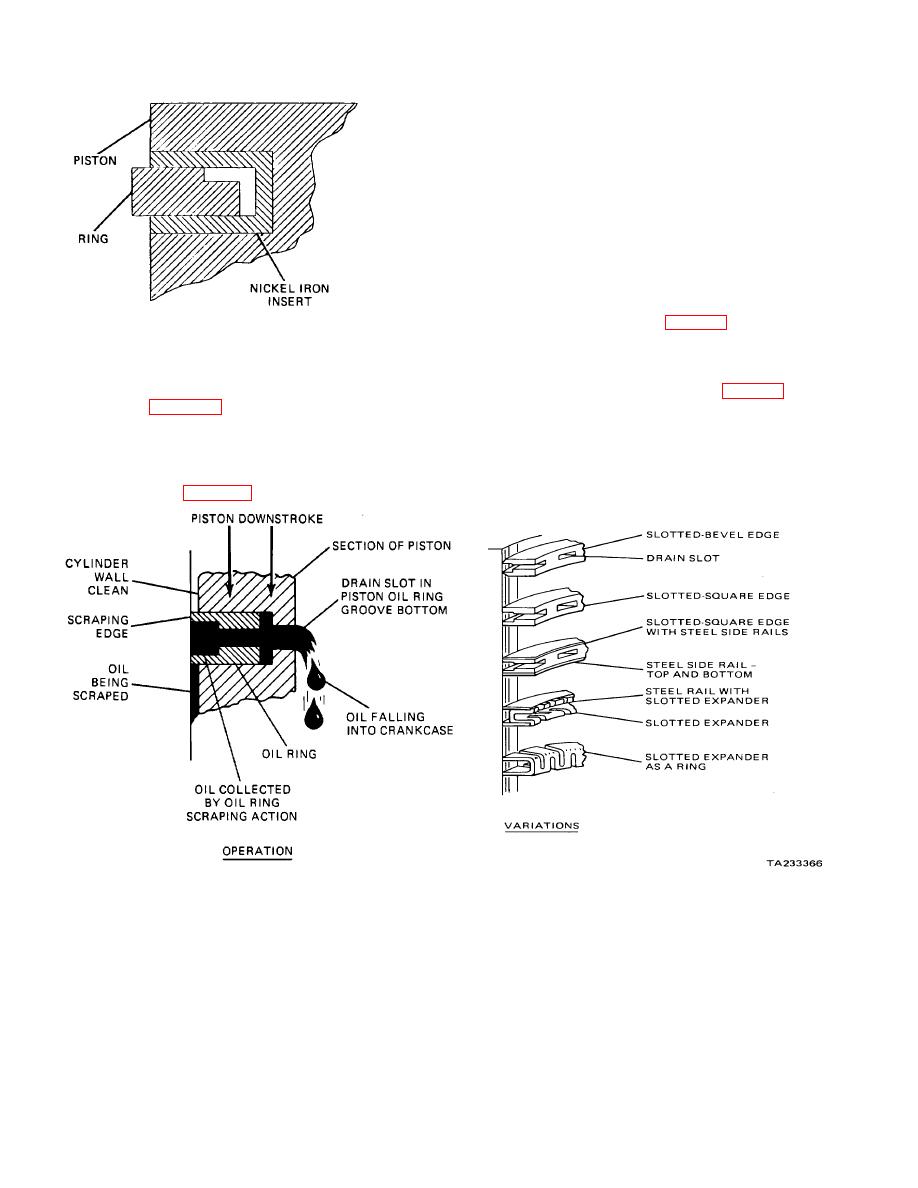

Figure 3-26. Top Ring Groove Insert.

connecting rod by a screw or friction. The pin pivots

freely in the piston pin bosses.

3-7. Piston Pins.

(3) The full-floating piston pins (C, fig. 3-32) pivot freely

a. General (Fig. 3-30). The piston pin serves to

in the connecting rod and the piston pin bosses. The

connect the piston to the connecting rod. It passes

outer ends of the piston pins are fitted with lockrings to

through the pin bosses in the piston and the upper end of

keep the pin from sliding out and contacting the cylinder

the connecting rod.

walls.

b. Construction (Fig. 3-31). A piston pin must be hard

Figure 3-27. Oil Control Rings

3-16

|

||

|

||