| Tweet |

Custom Search

|

|

|

||

TM 9-8000

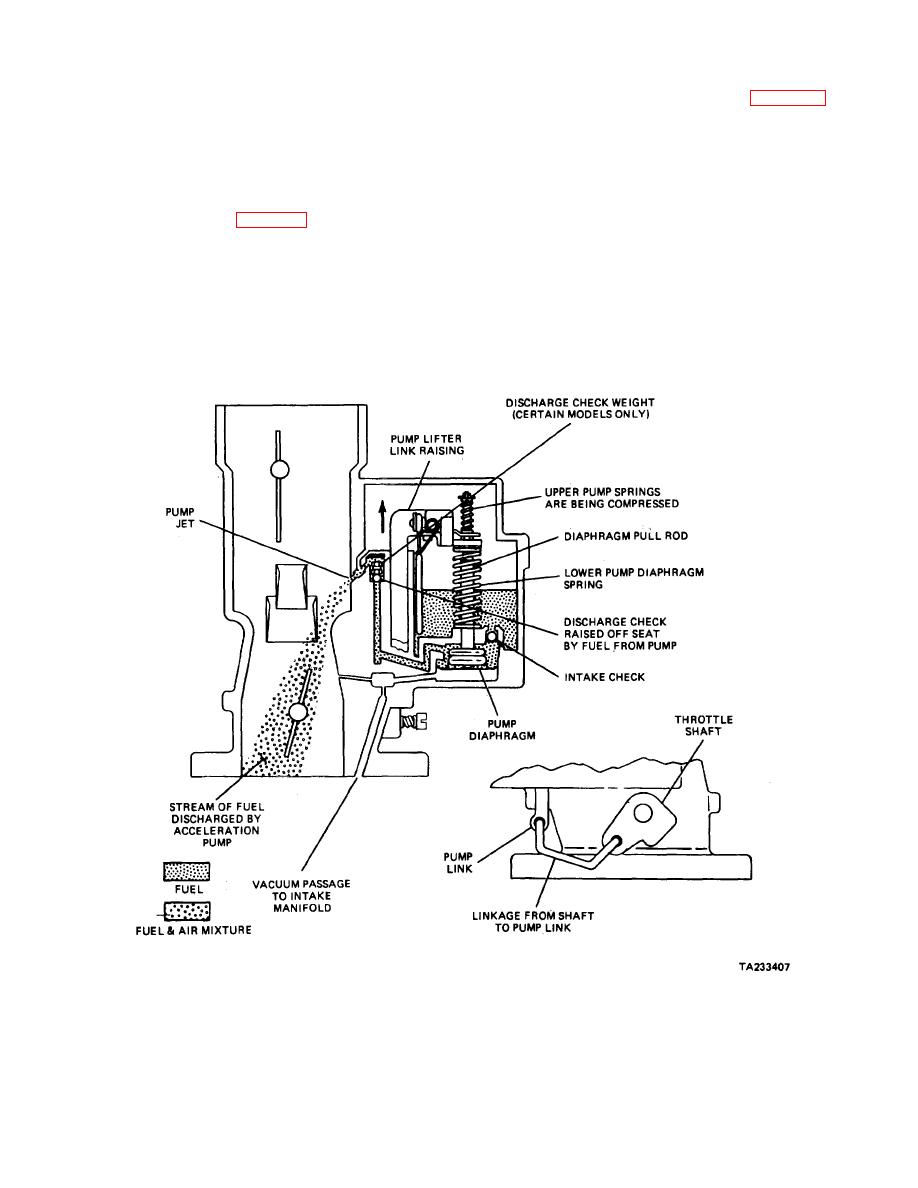

d. Controlling pump discharge (Fig. 4-36). The

(5) At the same moment, the inlet check ball is

pulled off its seat and gasoline is pulled into the pump

linkage between the accelerator pumpa6-hd the throttle

chamber from the float bowl

cannot be solid. If it were, the pump would act as a

damper, not allowing the throttle to be opened and closed

(6) The pump chamber is filled with gasoline and

readily. The linkage usually activates the pump through

ready to discharge whenever the throttle valve Is opened.

a slotted shaft or some- thing similar. When the throttle

is closed, the pump Is held by its linkage. When the

c. Diaphragm Pump (Fig. 4-35). The diaphragm-

throttle is opened, the pump is activated by being pushed

type pump system works just like the piston type with the

down by a spring that is called a duration spring. The

exception of the pump design, which is a flat rubber

tension of the duration spring controls the length of time

diaphragm.

By flexing this diaphragm, a pressure

that the injection of fuel lasts. The spring is calibrated to

differential is created that results In pump action.

specific applications. Too much spring pressure will

cause fuel to be discharged too quickly, resulting in

reduced fuel economy. Too little spring pressure will

cause fuel to be discharged too slowly, resulting In

engine hesitation.

Figure 4-35. Diaphragm Accelerator Pump.

Change 1 4-22

|

||

|

||