| Tweet |

Custom Search

|

|

|

||

TM 9-8000

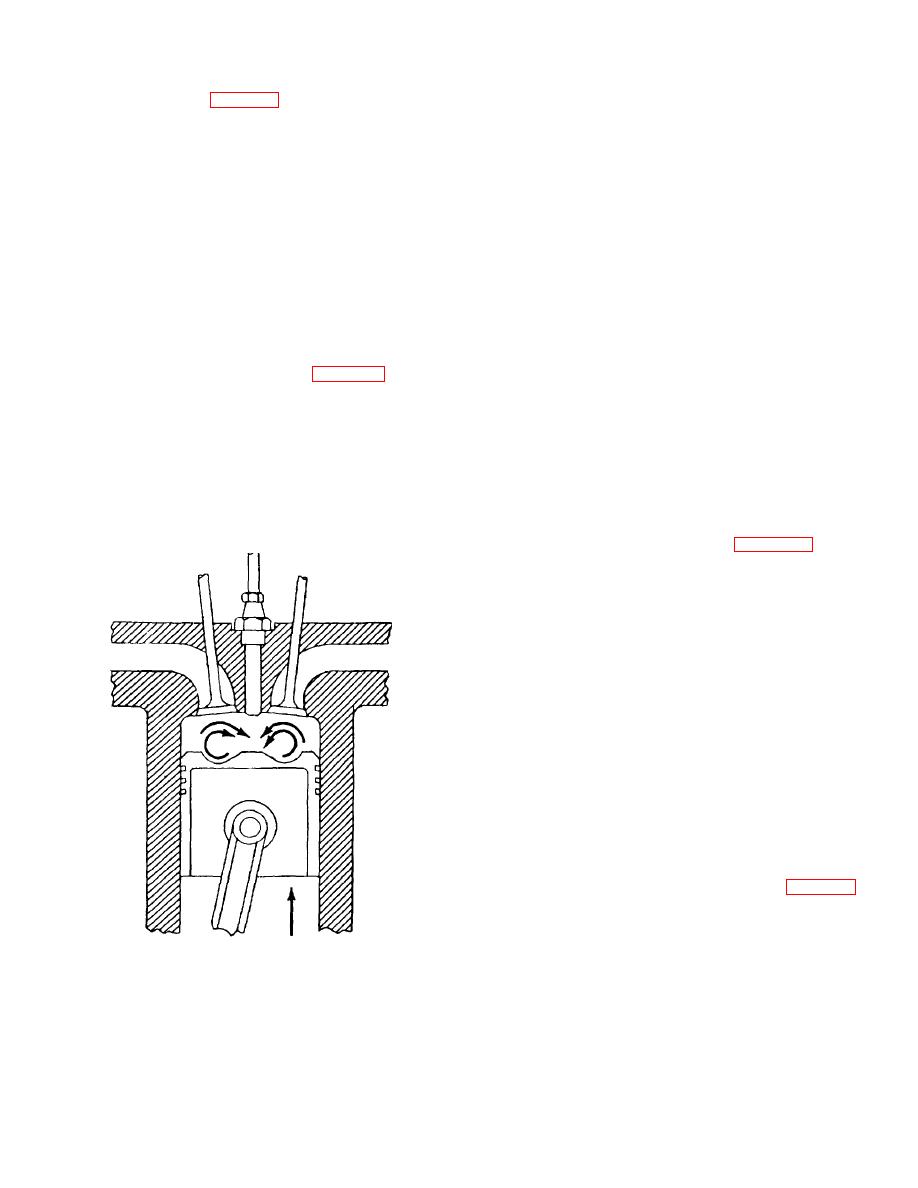

a. During the compression stroke of the engine, air

5-9.

is forced into the precompression chamber and, because

is the simplest form of chamber. It is suitable only for

the air compressed, it is hot. At the beginning of

slow-speed, four-stroke cycle engines, but is used widely

injection, the precombustion chamber contains a definite

in two-stroke cycle diesel engines. In the open chamber,

volume of air.

the fuel is injected directly into the space at the top of the

cylinder. The combustion space, formed by the top of

b. As the injection begins, combustion begins in the

the piston and the cylinder head, usually is shaped to

precombustion chamber.

The burning of the fuel

provide a swirling action of the air as the piston comes

combined with the restricted passage to the main

up on the compression stroke. There are no special

combustion chamber creates a tremendous amount of

pockets, cells, or passages to aid the mixing of the fuel

pressure in the precombustion chamber. The pressure

and air. This type of chamber requires a higher injection

and the initial combustion cause a superheated fuel

pressure and a greater degree of fuel atomization than is

charge to enter the main combustion chamber at a

required by other combustion chambers to obtain an

tremendous velocity.

acceptable level of fuel mixing. This chamber design is

very susceptible to ignition lag.

c. The entering mixture hits the hollowed-out piston

top, creating turbulence in the chamber to ensure

5-10. Precombustion Chamber (Fig. 5-3).

The

complete mixing of the fuel charge with the air. This

precombustion chamber is an auxiliary chamber at the

mixing ensures even and complete combustion. This

top of the cylinder.

It is connected to the main

chamber design will provide satisfactory performance

combustion chamber by a restricted throat or passage.

with low fuel injector pressures and coarse spray

The precombustion chamber conditions the fuel for final

patterns because a large amount of vaporization takes

combustion in the cylinder. A hollowed-out portion of the

place in the combustion chamber. This chamber also is

piston top causes turbulence in the main combustion

not very susceptible to ignition lag, making it more

chamber as the fuel enters from the precombustion

suitable for high-speed applications.

chamber to aid in mixing with air. The following steps

occur during the combustion process:

The

turbulence chamber is similar in appearance to the

precombustion chamber, but its function is different.

There is very little clearance between the top of the

piston and the head, so that a high percentage of the air

between the piston and the cylinder head is forced into

the turbulence chamber during the compression stroke.

The chamber usually is spherical, and the opening

through which the air must pass becomes smaller as the

piston reaches the top of the stroke, thereby increasing

the velocity of the air in the chamber. This turbulence

speed is approximately 50 times crankshaft speed. The

fuel injection is timed to occur when the turbulence in the

chamber is the greatest. This ensures a thorough mixing

of the fuel and the air, with the result that the greater part

of combustion takes place in the turbulence chamber

itself. The pressure created by the expansion of the

burning gases is the force that drives the piston

downward on the power stroke.

5-12. Spherical Combustion Chamber (Fig. 5-5).

The spherical combustion chamber is

TA233440

Figure 5-2. Open Combustion Chamber.

5-4

|

||

|

||