| Tweet |

Custom Search

|

|

|

||

TM 9-8000

the volume of fuel injected to the cylinders to be varied

in the delivery line combined with spring pressure causes

by changing the effective length of the pump stroke (the

the delivery valve to close. When the delivery valve

length of the pump stroke that occurs before the spill port

closes, It prevents fuel from the line from draining back

is uncovered by the bypass helix). The rack extends

Into the pump, which could cause the system to lose its

down the whole row of Injection pumps so that they are

prime. As the delivery valve seats, It also serves to

all operated simultaneously. The end result is that the

reduce pressure In the delivery line. The delivery valve

Injection pumps can be moved from full to no-fuel

has an accurately lapped displacement piston

delivery by moving the rack back and forth. The

Incorporated Into It to accomplish pressure relief. The

movement of the rack is controlled by the governor

pressure is relieved in the line by the Increase In volume

(para5-24).

as the delivery valve seats.

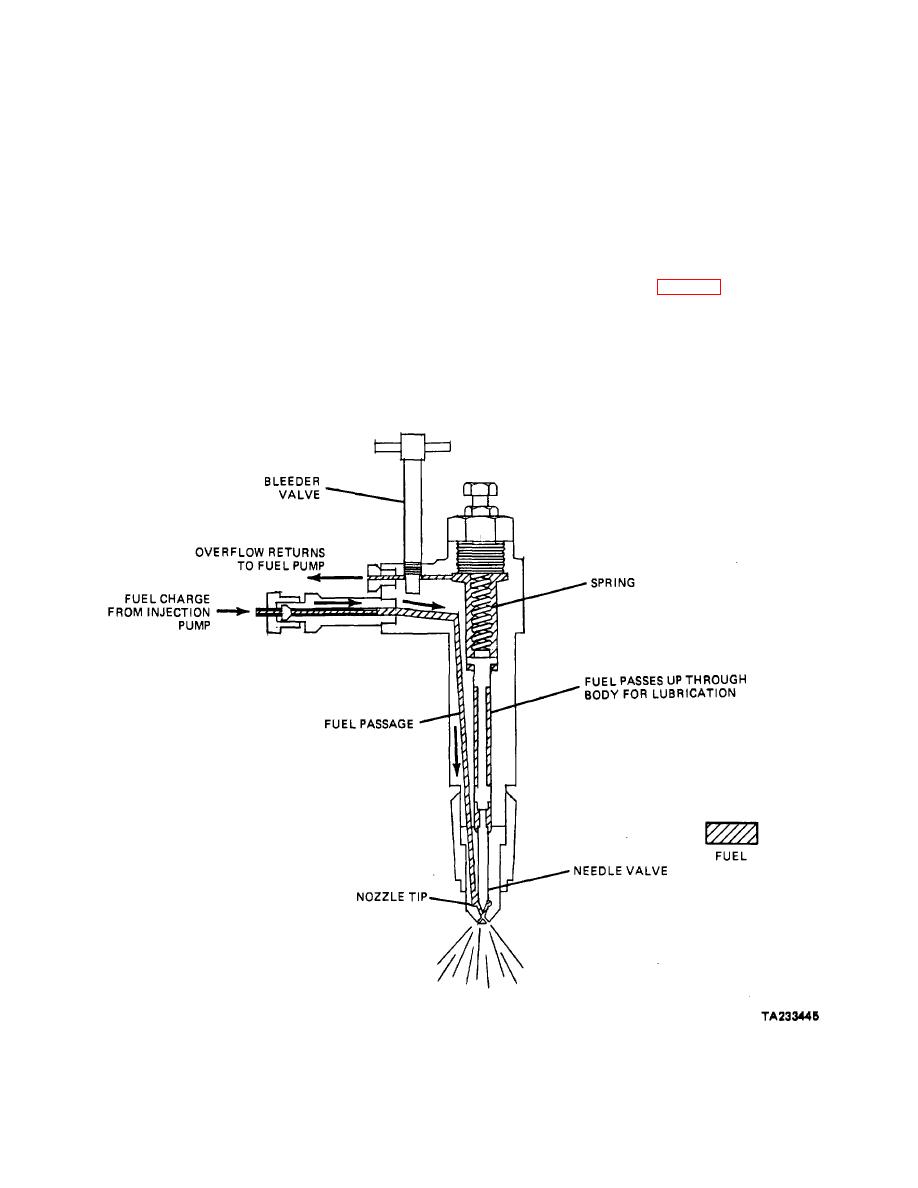

c. Fuel Injectors (Fig. 5-8). For proper engine

(5) When the plunger begins Its pump stroke It

covers both ports. When this happens, the pressure

performance, the fuel must be Injected Into the

exerted on the fuel causes the spring-loaded delivery

combustion space In a definite spray pattern. This is

valve to lift off of Its seat, thereby permitting fuel to

accomplished by the fuel Injector.

discharge Into the tubing that leads to the spray nozzle.

At the Instant that the bypass helix uncovers the spill

(1) The fuel enters the nozzle holder body

port, the fuel begins to bypass. This causes the

through the high-pressure Inlet. It then passes

pressure In the pump cavity to drop. The high pressure

Figure 5-8. Multiple Unit Injector.

5-11

|

||

|

||