| Tweet |

Custom Search

|

|

|

||

TM 9-8000

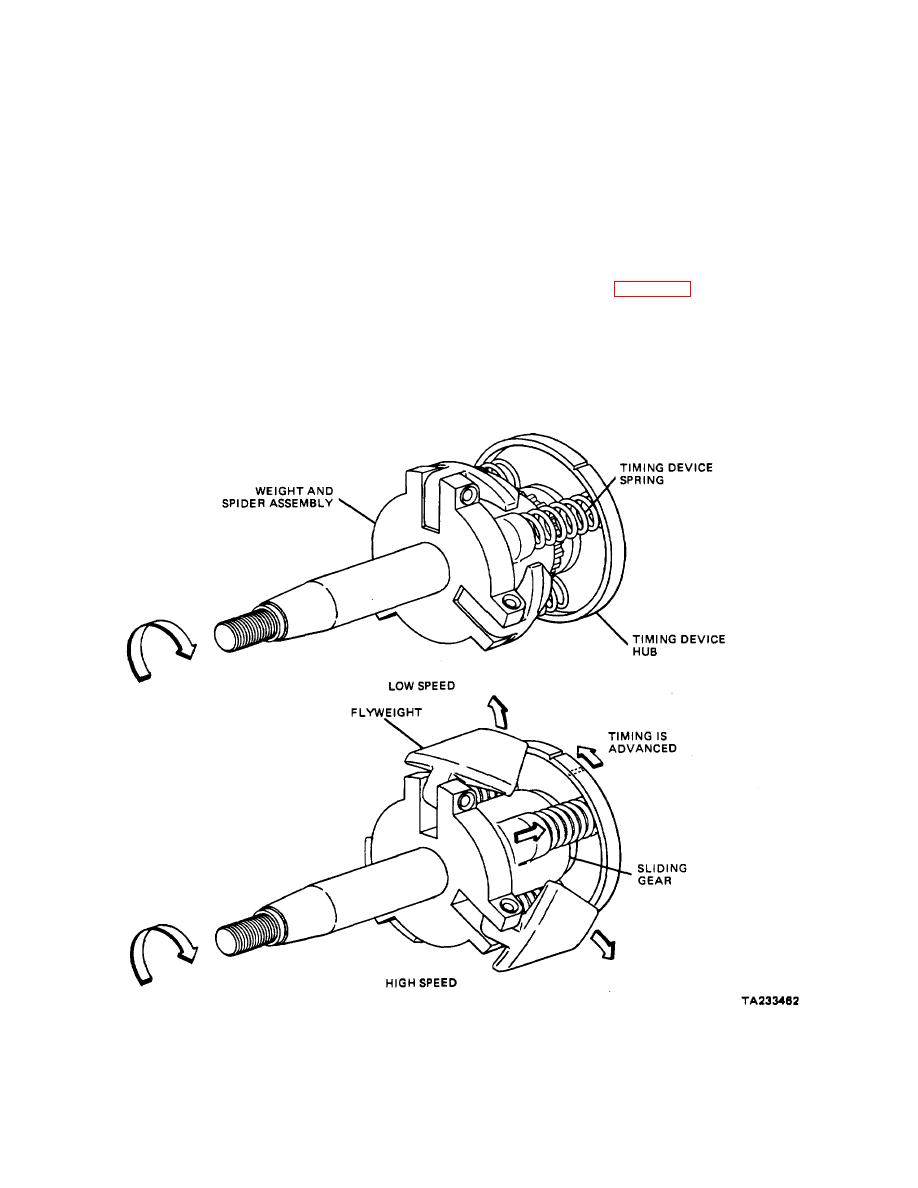

bore and keyway. The hub Is secured to the camshaft

both the weight and spider assembly and the timing

extension by a woodruff key, nut, and setscrew. The

device hub.

Correct assembly of the spline train is

hub usually Is counterbored to receive the timing device

ensured by a wide land on both the hub and weight and

springs. The springs oppose the flyweight forces of the

the spider assembly. The sliding gear has a missing

weight and spider assembly.

tooth on each set of Internal splines to receive the wide

lands. Three arms extend from the outer surface of the

c, The weight and spider assembly has external

sliding gear to provide seats for the three timing device

right-hand helical splines to mesh with the Internal helical

springs. The force on these springs Is controlled by a

splines of the sliding gear. The spllned end is machined

sliding gear spacer.

to receive the end play spacer. Three flyweights are

pinned to a flange adjacent to the spilnes. The weight

5-30.

Operation (Fig. 5-26).

and spider thrust plate located between the flange and

the timing device housing carries the back thrust of the

a. As the engine rotates the weight and spider

flyweights and prevents housing wear.

assembly, centrifugal force opens the flyweights from

their collapsed position against the force of the three

d. The sliding gear has Internal left-hand helical

timing device springs.

splines at one end and Internal right-hand helical splines

at the other end and meshes with the external splines of

Figure 5-26. Timing Device Operation.

5-34

|

||

|

||