| Tweet |

Custom Search

|

|

|

||

TM 9-8000

in the two sides A and B of the loop, and the consequent

armature rotation. They are constructed of heavy copper

field distortion (2, fig. 14-1), A will be repulsed upward

wire that is usually rectangular in cross section. An

and B downward, and the loop will rotate in a clockwise

insulating material is placed within the windings to

direction.

insulate the coils from each other. The coils then are

insulated on the outside by either wrapping them in

paper or sealing them in rubber. The field coils are

14-3.

Automotive Starting Motor.

secured to the field frame by the pole shoes. The pole

shoes serve as a core for the field coils to increase

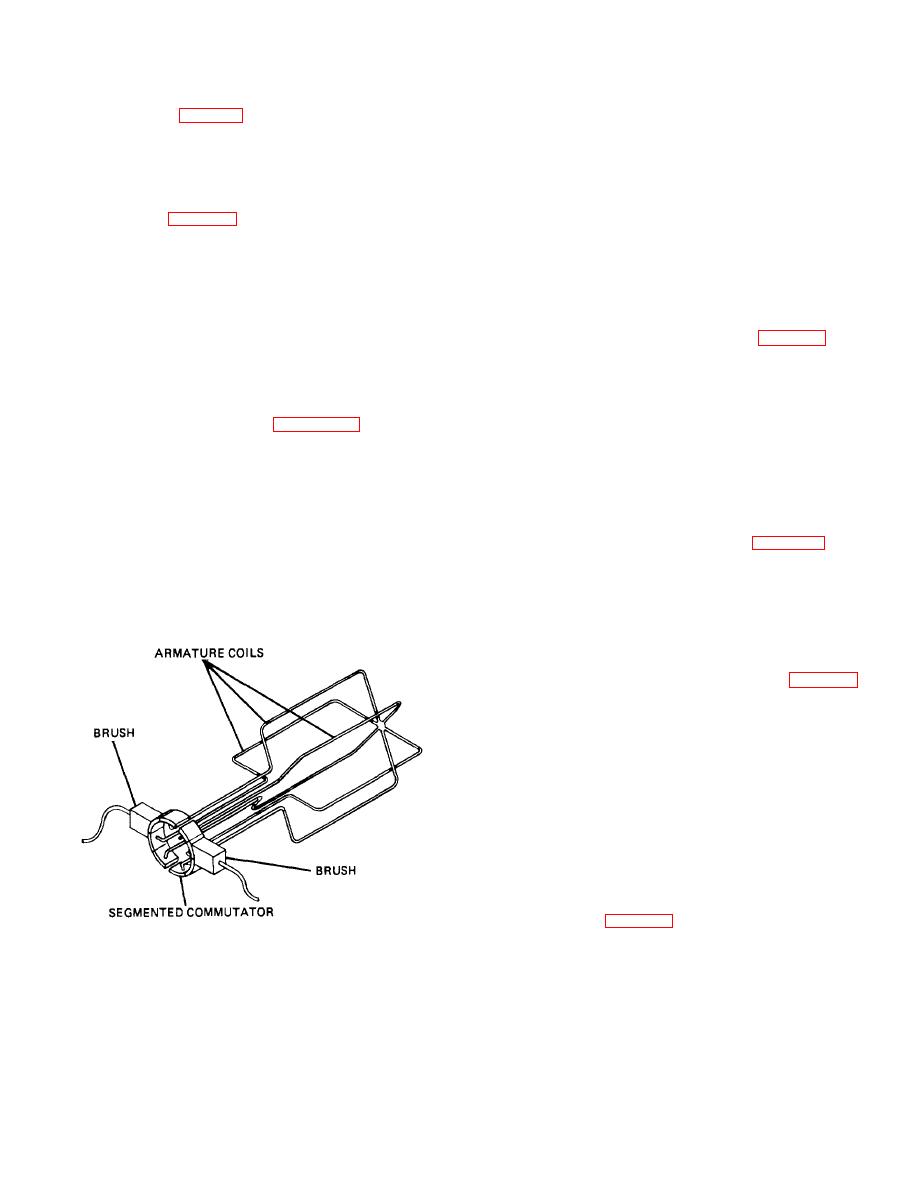

a. General (Fig. 14-2). In use, the motor armature

permeability.

has many armature coils equally spaced around the

entire circumference of the armature. Each of these

c. Field Circuit Configurations. Field circuits will

coils carries current and consequently exerts a force to

vary according to the application of the starter. The

rotate the armature as it passes the pole pieces. The

following are the most popular.

switching of the armature coils to the brushes is handled

by a segmented commutation.

The result is a

(1) Two Windings: Parallel (A, fig. 14-4). The

comparatively high turning power (or torque) that is

wiring of two field coils in parallel will increase their field

sufficient to crank the engine if it is applied through

strength because they each receive full voltage. Note

suitable gear reductions.

that two additional pole shoes are used. Though they

have no windings, their presence will strengthen further

b. Construction. A cutaway view of a typical

the magnetic field.

automotive starter is shown in figure 14-3. The basic

motor consists of the following parts.

(2) Four Windings: Series-Parallel (B, Fig. 14-

4). The wiring of four field coils in a series-parallel

(1) Armature. The armature contains multiple

combination will create a much stronger magnetic field

loops of heavy copper. These coils pass through a

than the two field coil configuration described above.

laminated core of iron to increase the permeability of the

armature. The commutator segments are made of

(3) Four Windings: Series (C, Fig. 14-4). The

heavy copper bars that are set into mica or epoxy resins.

wiring of four field coils in series will provide a large

The armature rotates on bronze bushings.

amount of low-speed starting torque, which is a very

necessary characteristic of an automotive starting motor.

(2)

Field Coils.

The field coils

An undesirable characteristic of series-wound motors is

electromagnetically create the magnetic field that cause

that they will build up excessive speed if allowed to run

free to the point where they will destroy themselves.

(4) Six Windings: Series-Parallel (D, Fig. 14-4).

Three pairs of series-wound field windings provide the

magnetic field for a heavy-duty starter.

This

configuration uses six brushes.

(5) Three Windings: Two Series, One Shunt (E, Fig

. 14-4). The use of one field coil that is shunted to

ground with a series-wound motor will control motor

speed. The shunt coil, because it is not affected by

speed, will draw a steady, heavy current, effectively

limiting speed.

14-4.

Starter Motor Drives.

a. General (Fig. 14-5). The starter may drive the

engine through a pinion or by a dog clutch attached to

Figure 14-2. Automotive Starting Motor

the starter armature shaft. The shaft is brought together

TA233575

14-2

|

||

|

||