| Tweet |

Custom Search

|

|

|

||

TM 9-8000

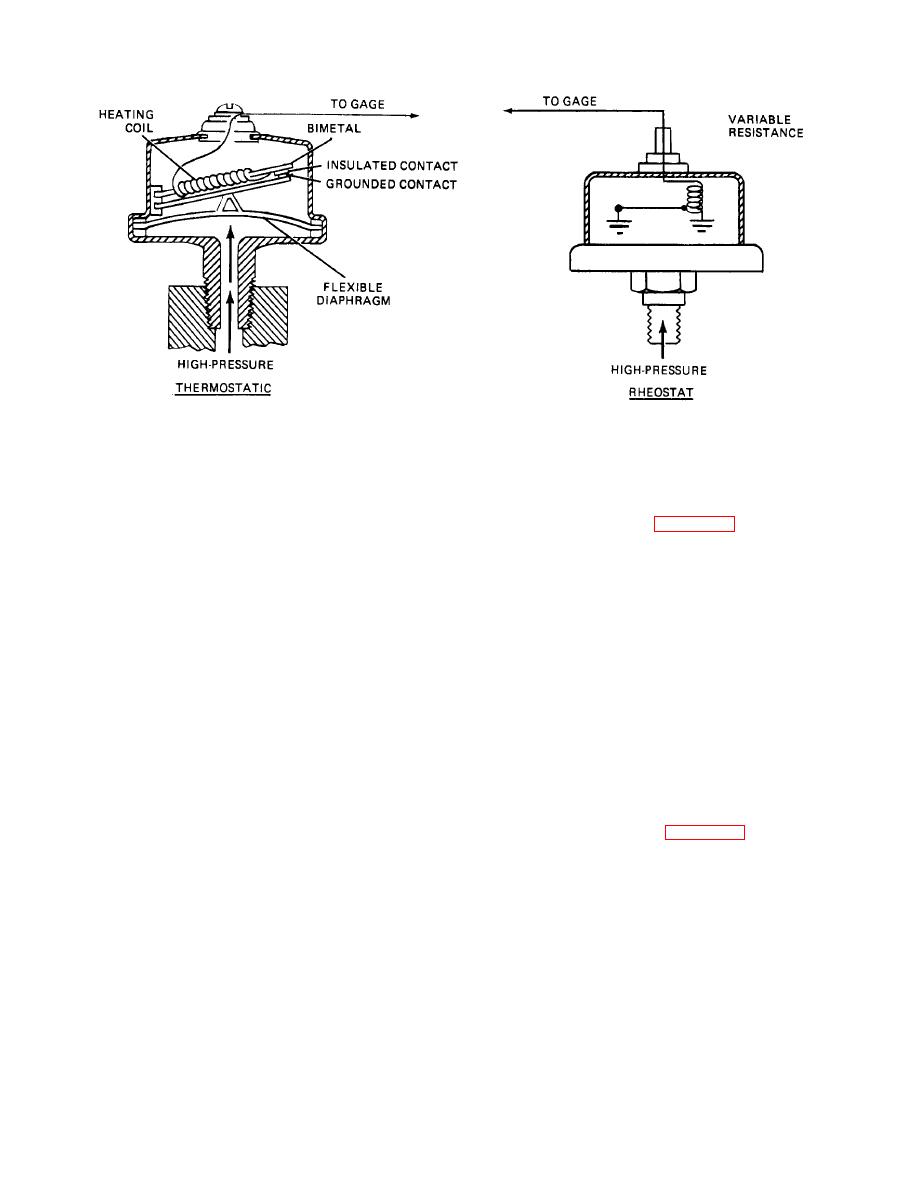

Figure 17-10. Types of Sending Units for Pressure Gages

unit that Is used with each gage type varies as follows:

tube, it will tend to straighten out. As it straightens, the

attached gage pointer will move, giving a reading

(1) The sending unit that Is used with the

d. Indicator Lamp (Fig. 17-12). The oil pressure

thermostatic gage utilizes a flexible diaphragm that

moves a grounded contact. The contact that mates with

warning light Is used In place of a gage on many

the grounded contact Is attached to a heated bimetallic

vehicles. The warning light, although not an accurate

strip. The flexing of the diaphragm, which Is done with

indicator, Is valuable because of Its high visibility in the

pressure changes, varies the point tension. The different

event of a low oil pressure condition. Because an engine

positions of the diaphragm produce gage readings In the

can fail or be damaged permanently in less than a

same manner as the different positions of the float arm

minute of operation without oil pressure, the warning light

of the tank sender In paragraph 17-3a.

often Is used as a backup for a gage to attract Instant

attention to a malfunction. The warning light receives

(2) The sending unit that Is used with the

battery power through the ignition switch. The circuit to

magnetic-type gage also translates pressure Into the

ground is completed through the engine sender switch.

flexing of a diaphragm. In the case of the magnetic gage

The sender switch consists of a pressure-sensitive

sending unit however, the diaphragm operates a

diaphragm that operates a set of contact points. The

rheostat. The flexing of the diaphragm In the pressure

contact points are calibrated to turn on the warning light

sender produces the same results as does the

whenever the engine oil pressure drops below

movement of the float arm In the tank sender described

approximately 15 psi (103.4 kPa), depending on the

In paragraph 17-3d. This type of sender also can be

equipment.

used with a thermostatic-type gage If a voltage-limiting

de- vice like the one used In paragraph 17-3b also Is

17-5. Temperature Gages(Fig. 17-13).

used.

a. Usage. The temperature gage Is a very Important

c. Mechanical Gages (Flg. 17-11). The mechanical

indicator In automotive equipment. The most common

pressure gage uses a thin tube to carry an actual

use Is to Indicate engine, transmission, and differential

pressure sample directly to the gage. The gage basically

oil temperatures and engine coolant temperatures.

consists of a hollow, flexible C-shaped tube called a

Depending on the type of equipment, the gage may be

bourden tube. As fluid or air pressure Is applied to the

electric

or

mechanical.

TA233627

bourden

17-8

|

||

|

||