| Tweet |

Custom Search

|

|

|

||

TM 9-8000

torque increase (or torque multiplication) may be much

transmitted through the system. If a large resistance

greater than 12:1.

must be overcome, the torque multiplication also must be

high. If this factor is not correct, the driving system can

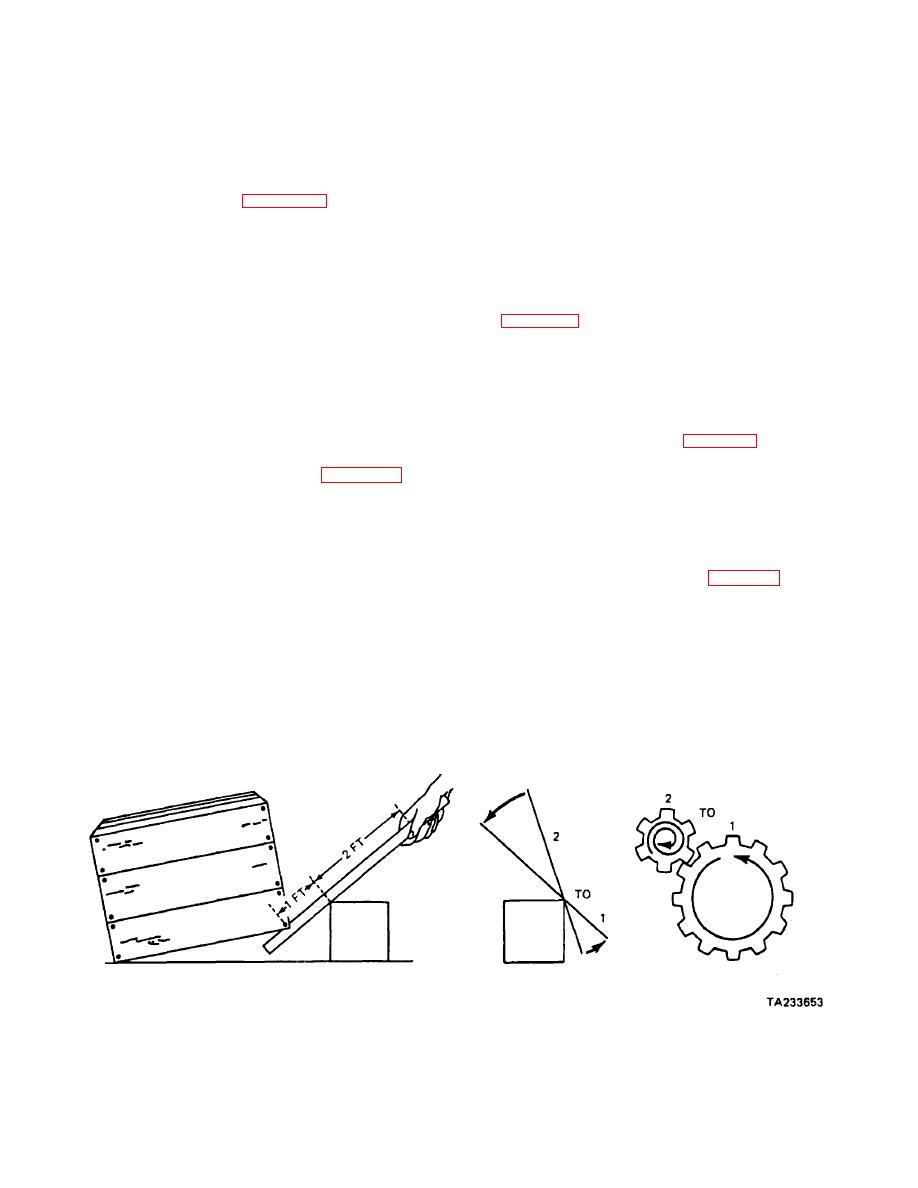

b. Mechanical Advantage. The use of a lever to

be overloaded. On the other hand, if a small resistance

is to be overcome, the driving system might not be used

move heavy objects is well known. When a box is too

to its fullest capabilities, therefore producing an inefficient

heavy to be lifted by hand, a crowbar or lever can be

system.

used to lift it, as shown in figure 19-3. With the lever

placed as shown, only half as much force is required on

e. Internal and External Gears. Gears are basically

the lever to raise the box. Suppose that a lifting force of

of two types: internal and external. Internal gears are

200 pounds is required to raise the end of the box. With

shaped cylindrically with teeth machined on the inside.

the lever arranged as shown, only a 100-pound

External gears usually are circular with teeth around the

downward push is needed on the lever. The farther out

outside of the gear. An example of both gears is shown

on the lever the hand is put (away from the pivoting point,

in figure 19-4.

or fulcrum), the less downward push is required. But

also, the farther the hand must move to raise the box.

The mechanical advantage of the lever is the ratio

19-4. Types of Gears. There are many types and

between the two distances from the fulcrum. In the

designs of gears and gear systems. Some of the most

example shown, the mechanical advantage is 2:1.

popular gears found in the automotive vehicle are

discussed below.

c. Mechanical Advantage in Gears. A rough

comparison between mechanical advantage in levers

a. Spur. Spur gears (fig. 19-5) are the most

and mechanical advantage in gears can be made. Such

common type of gear.

The teeth are machined

a comparison is shown at the bottom of figure 19-3. One

perpendicular to the axis of rotation. Because these

end of the lever moves twice as far as the other. When

gears mesh only one tooth at a time, they are not

two gears are meshed and one gear has twice as many

capable of absorbing great amounts of torque. They

teeth as the other, the smaller gear will rotate twice for

generally are noisy during operation and are used to

each revolution of the larger gear. In other words, the

change direction and/or speed.

mechanical advantage between the two gears would be

1:2 when the larger gear drove the smaller gear. If the

b. Helical. Helical gears (fig. 19-5) have teeth

smaller gear drove the larger gear, the mechanical

machined at an angle to their centerline of rotation. This

advantage would be 2:1 because the smaller gear would

characteristic enables the gear to engage more than one

have to exert half the force for twice the distance.

tooth at a time. This type of gear, therefore, is stronger

and able to transmit more torque than spur gears.

d.

Mechanical Efficiency.

The mechanical

Because of the angle cut of the gear, two meshing gears

efficiency of a system is dependent upon gear ratios and

tend to move apart during use. This reaction therefore

the amount of power that must be

requires the use of a thrust washer or tapered bearing

when using helical gears. Helical gears

Figure 19-3. Mechanical Advantage.

19-4

|

||

|

||