| Tweet |

Custom Search

|

|

|

||

TM 9-8000

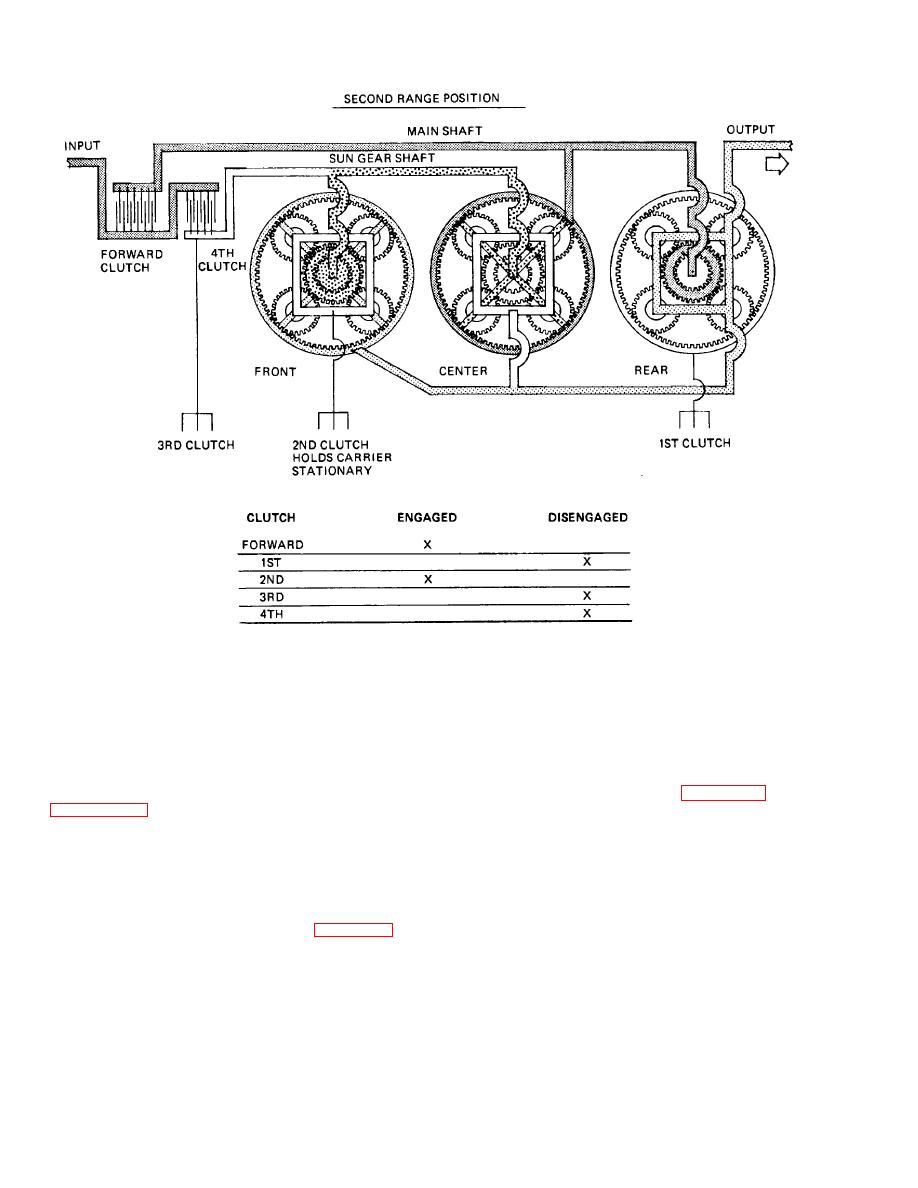

Figure 25-6. Power Flow through X1100 Transmission in Second Range

The pressurized control piston rotates the hang- ing ring

pump circuit as required to replenish oil lost in leakage

to a position that causes the hydrostatic pump pistons to

during overload, or in control functions. The other valve

reciprocate. The length of their stroke corresponds to

remains closed. The direction of rotation determines

the degree of steer ap- plied, and the hydraulic output of

when each valve is opened or closed. Oil is supplied

the hydrostatic pump is directly proportional to the stroke.

through the open valve to the input side of the hydrostatic

Oil flow from the moving pistons now is directed to the

pump.

proper port of the motor. This produces the movement

required to drive the sun gears of the planetary gearsets.

b. Control Pumps (Fig. 25-12). The control

pumps further pressurize the oil before it is directed to

right steering.

the hydrostatic pump control system. The output of the

control pumps is directed to three points: the first point is

the control pressure regulator valve; the second is the

25-7. Components. In addition to the components

secondary control pressure regulator; and the third is the

mentioned above, other elements are used in the

rotary servo unit.

steering system. Each is discussed below.

c. Servo Sleeve. The servo sleeve is a rotating

a. Supercharge Check Valves (Fig. 25-12). Two

sleeve valve with ports to direct control pressure to the

supercharge check valves are provided in the line

control pistons. The servo sleeve is centered on the

between the main pressure regulator and the hydrostatic

same axis as the hanging ring (mechanism that controls

pump. One check valve is open at all times to provide

the pump piston stroke) and is

additional oil to the hydrostatic

TA233747

25-6

|

||

|

||