| Tweet |

Custom Search

|

|

|

||

TM 9-8000

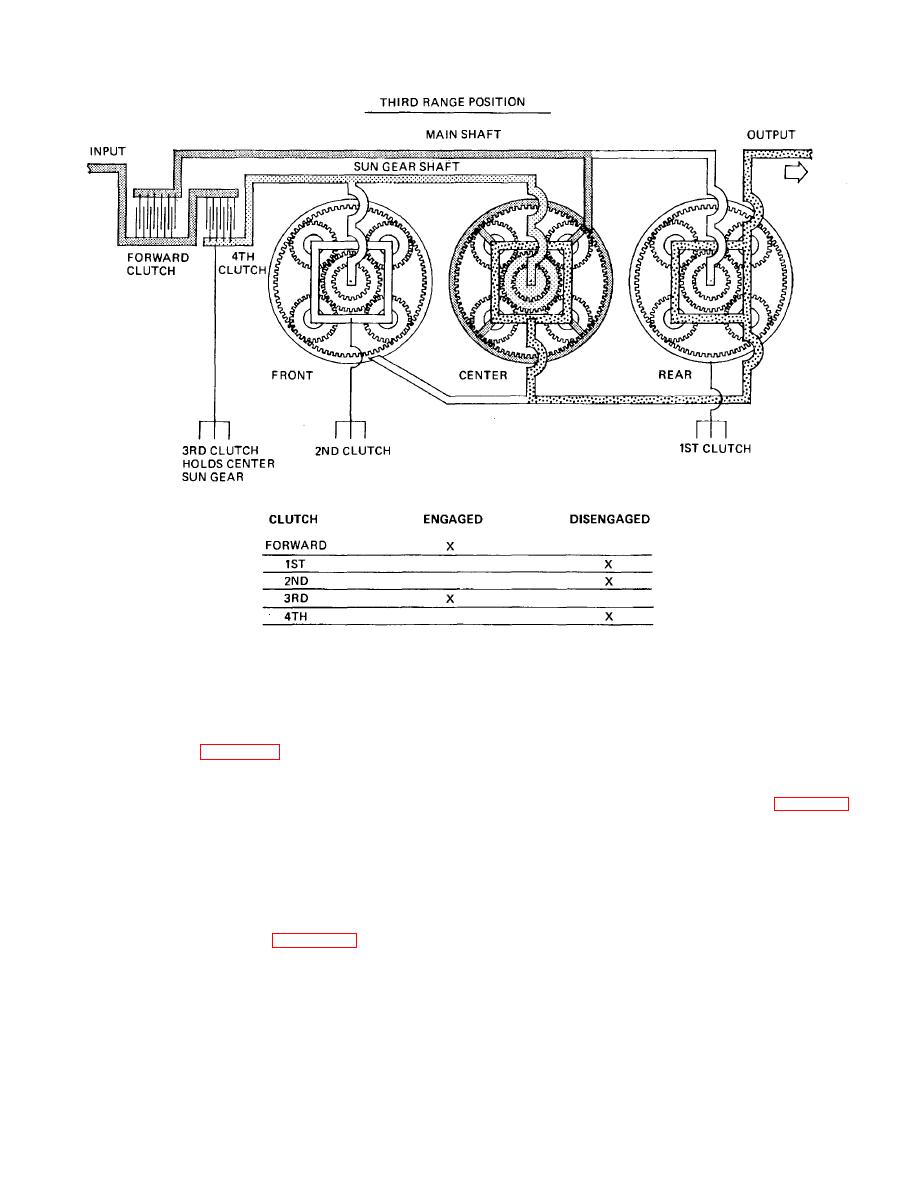

Figure 25-7. Power Flow through X1100 Transmission in Third Range

connected to the hanging ring by a pin. The pin transmits

a position that interrupts the control pressure circuit

the partial rotation of the hanging ring to the servo

actuating the control pistons. This action overrides steer

sleeve.

control to the extent of reducing steer to the degree

possible under overload conditions.

d. Servo Valve (Fig. 25-12). Centered within the

servo sleeve is the manually controlled servo valve

25-8. Final Drive.

which, when rotated, directs control pressure to either of

the two control pistons. Clockwise rotation of the servo

a. General. The final drive assembly (fig. 25-15) is

valve from its normally centered position gives steer in

a self-contained, heavy-duty planetary gear speed-

one direction; counterclockwise rotation gives steer in the

reduction unit. The input spline is integral with the

other direction. The control pistons have no pressure

planetary sun gear. The planetary ring gear is bolted to

acting upon them when no steer is applied. Their oil lines

the final drive housing and, therefore, is stationary. The

are open to exhaust through the servo

planetary carrier, with planet pinion gears, is splined to

valve.

the output shaft. The final drive unit is identical for both

left and right transmission outputs. The dry weight of

e. Stroke Limiter Valve (Fig. 25-12). A stroke

each final drive is approximately 940 lb.

limiter valve is provided in the control circuit. Under

normal condition the valve remains in the position shown.

The oil supply is contained in the bottom of the housing

Under conditions that overload the hydrostatic pump

and provides both cooling and lubrication for the unit.

(approximately 5000 psi), the excessive output pressure

Lubrication is obtained by the splash

pushes the valve to

TA233748

25-7

|

||

|

||