| Tweet |

Custom Search

|

|

|

||

TM 9-8000

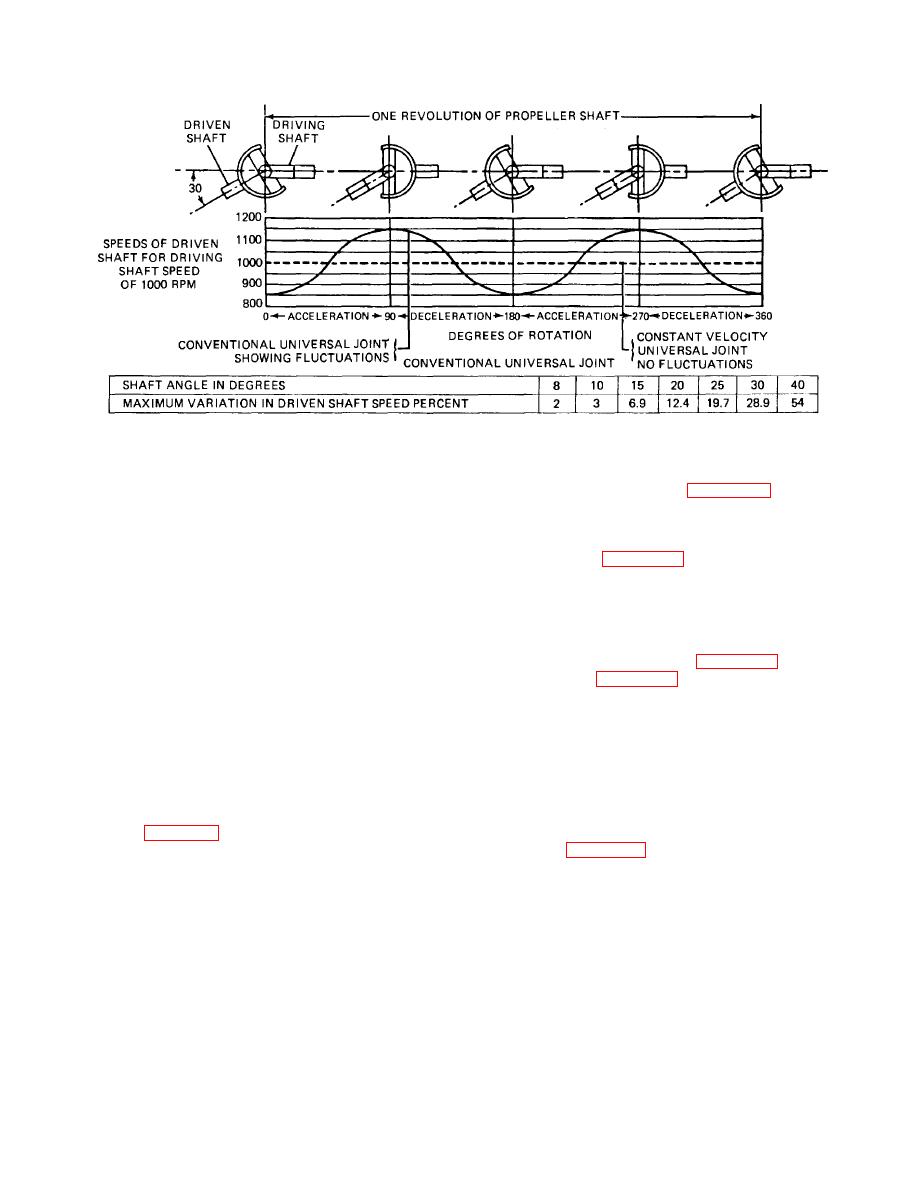

Figure 28-3. Speed Fluctuations Caused by Conventional Universal Joints.

are employed, the second joint is used to compensate

which are shown in A and B, figure 28-4. The different

for the speed fluctuations caused by the first. In order to

universal joints of this type vary from each other mainly

accomplish this, the angle between the transmission

in the manner in which the journal is attached to the

shaft and the propeller shaft must be the same as the

driving and driven yokes. For example, in the universal

angle between the propeller shaft and the final drive of

joint shown in A, figure 28-4, the journal is assembled in

the rear axle. Another requirement is that the two yokes

the shaft and slip yokes, the bearing assemblies inserted

of the universal joint that are attached to the propeller

from the outside and secured by spring bearing retainers

shaft be in the same plane. If the yokes of the joints

inside the yokes. The bearings on the transverse ends

attached to the propeller shaft are in the same plane, the

of the journal are clamped to the flange yokes and

driving yoke of the first joint will be at an angle of 90

secured from outward movement by bearing retainers.

degrees with the driving yoke of the second. The two

The universal joint shown in A, figure 28-4, differs from

yokes attached to the propeller shaft act as the driven

that shown in B, figure 28-4, in the manner in which the

yoke of the first joint and the driving yoke of the second

journal is attached to the flange yoke. In this universal

joint, respectively. With this arrangement, the first joint is

joint, the bearing assembly is contained in bearing

producing its maximum fluctuation at the same time the

blocks. The blocks are mounted against the flange

second joint is producing its minimum fluctuation. This

yokes and secured with bolts extending longitudinally

results in a nonvarying wheel speed for a given engine

through the yokes.

speed, even though the speed of the shaft between the

b. Ball and Trunnion. Two universal joints of the

joints is changing constantly.

ball-and-trunnion type are used in an application, one on

each end of the propeller shaft. This type of joint is

shown in C, figure 28-4. There is a trunnion pin through

bearings are included at the four points where the journal

the end of the propeller shaft. The pin is fitted with balls

is attached to the yokes. In addition, one of the yokes

that ride in grooves in the flanged body. The balls are

usually incorporates a splined slip joint. In one type of

assembled on bearings so they can rotate with little

universal joint (the ball-and-trunnion type), the universal

friction. Compensated springs at each end of

joint itself incorporates a feature that permits variations in

TA233771

length of the propeller shaft.

a. Journal-Type Universal Joint. There are

several variations of this type of universal joint, two of

28-3

|

||

|

||