| Tweet |

Custom Search

|

|

|

||

TM 9-8000

universal joints are necessary in the power shafts of this

design, because the swinging-arm pivot axis is out of line

with the power shaft. The pivot axis, however, does pass

through the inboard universal joint to minimize the

relative sliding motion of the splined coupling.

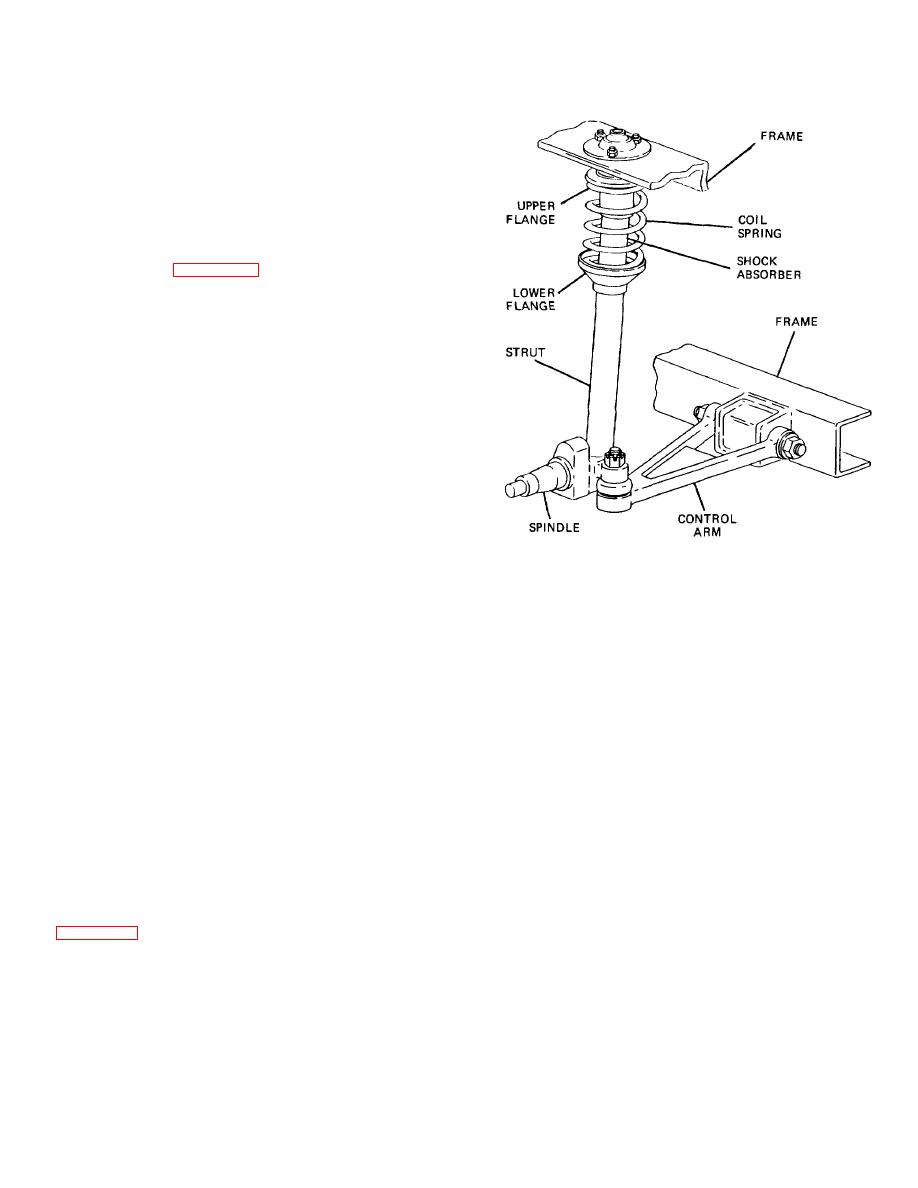

30-8.

MacPherson Struts.

The MacPherson

suspension system uses a tubular strut, which houses

the shock absorber mechanism and links the wheel and

body together (fig.

The strut usually is

surrounded by a coil spring attached to the top of the

strut, which is mounted to the body. The lower half of the

spring is mounted by a flange that is attached to the

bottom half of the strut, which is mounted to the spindle

or control arm.

There are also other types of

configurations in which the spring is mounted next to the

strut; this type makes replacement of the strut relatively

easy.

30-9.

Comparison.

The

development

of the

independent suspensions came about mostly to reduce

the unsprung mass, thereby improving the handling and

traction of high-speed road cars. However, the demand

for greater speed and mobility for military vehicles

warrants the use of independent suspension on such

vehicles. In addition to the improved performance

Figure 30-13. MacPherson Strut Suspension.

associated with reduced unsprung mass, the use of

independent suspensions increases the speed and

maintenance. The separate rigid members used to

mobility of the military vehicle by reducing front end

maintain wheel alinement require more careful design,

vibration (wheel shimmy and axle tramp), permitting the

expensive machining, and costlier bearings than the

use of softer suspension springs, providing more ground

simple solid axle, leaf-spring suspension. The pivot

clearance, and permitting more optimum wheel spacing.

bearings must be lubricated properly so that excessive

clearances will not cause vibrations and disturbances in

The disadvantages of independent suspensions for

the steering and suspension systems. The independent

military vehicles are primarily those of cost and

suspension is not as rugged as the solid axle type,

although continuing development of the independent

suspension for military vehicles may minimize these

disadvantages.

Section IV. HEAVY VEHICLE SUSPENSION

if the secondary spring is secured to the frame. From

30-10.

Springs.

Several configurations of spring

that point on, the two springs carry the load jointly and

suspension have been used for vehicles that carry widely

their load ratings are added. This allows the vehicle to

varying loads, to provide the necessary variable load

carry heavy loads without deflecting the mainsprings.

rate.

b. Another method of suspension that also provides

a. Auxiliary springs, often called secondary springs

a spring with variable load rating is shown in figure 30-

15. The spring is made with flat ends that bear against

mainspring to accomplish this purpose. When the load

curved bearing plates.

on the spring reaches a certain amount, the deflection of

the mainspring brings the free ends of the secondary

spring against bearing plates on the frame, or on the axle

TA233807

30-9

|

||

|

||