| Tweet |

Custom Search

|

|

|

||

TM 9-8000

energy of the road shock, rather than just one end.

raised or lowered half this amount. In this manner, bogie

Thus, the effect of road shocks is cut in half. When only

axles reduce by half the impact or shock not only to the

one axle is deflected up or down from its normal loaded

vehicle, but also to the road.

position, the trunnion axle and the vehicle frame are

Section V. AIR-OVER-HYDRAULIC SUSPENSION

the intake valve is opened by the linkage, allowing

30-13. Purpose. The air-over-hydraulic suspension

pressure to increase in the shock absorber. This, in turn,

system is designed to keep the body level under different

raises the vehicle to its normal position. As soon as the

loading conditions.

When the vehicle weight is

vehicle is level, the intake valve closes and a steady

increased, either by adding cargo or passengers, the

pressure is maintained in the shocks. When weight is

body will become lower to the ground. The leveling

removed from the vehicle, the linkage opens the exhaust

system then will sense a low condition and allow

valve and pressure is released in the shocks, restoring

pressure to increase in the special shock absorbers,

the vehicle to a normal riding position. The linkage also

raising the body with respect to the ground. When the

is dampened through the use of a fluid to prevent the

weight is removed, the system will allow air pressure to

control valve from reacting to bumps and changes in

bleed from the air shock absorbers, restoring the vehicle

road conditions.

to its normal riding height.

30-14. Components of Air-Over-Hydraulic

Suspension.

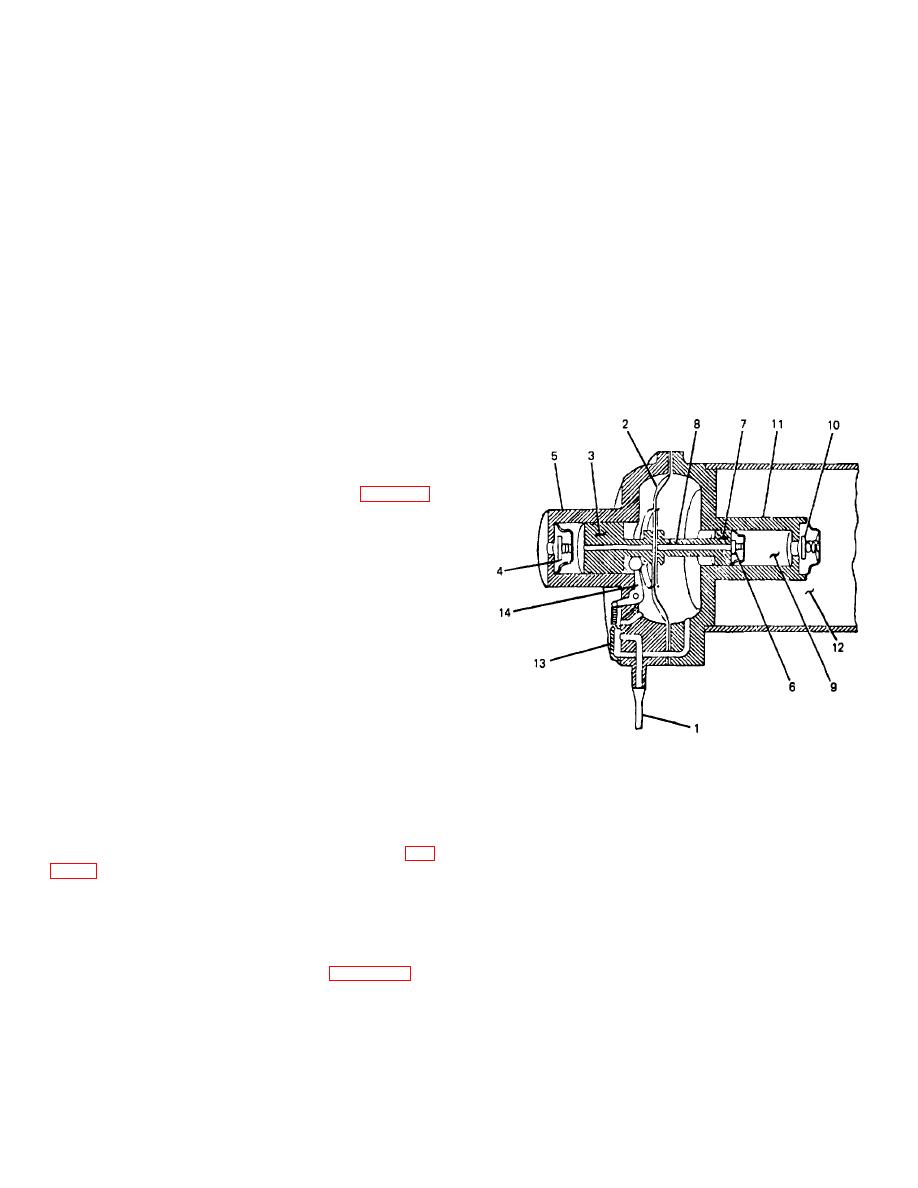

a. Air Compressor. The air compressor (fig. 30-

17) is commonly a vacuum-operated two-stage unit

requiring no lubrication. The sliding distributor valve

directs intake manifold vacuum alternately to the right or

left side of the diaphragm, moving it from side to side.

When the diaphragm, which is connected to a double

piston, moves to the right, it allows air to enter the first

stage chamber. At the end of the stroke, the check valve

on that chamber closes, and the distributor valve diverts

the vacuum to the opposite side of the diaphragm. As

the piston then moves to the left, the air in the first stage

moves through the air passage in the center of the piston

to the second stage chamber. At the end of that stroke,

the check valve on the air passage closes and, as the

piston moves to the right again, the check valve on the

1. VACUUM LINE

8. AIR PASSAGE

second stage cylinder opens, allowing the compressed

2. DIAPHRAGM

9. SECOND-STAGE

air to enter the air reservoir tank. As pressure in the

CYLINDER

reservoir tank builds up to a predetermined amount, it

3. PISTON

10. CHECK VALVE

puts an equal force on the second stage piston and the

4. CHECK VALVE

11. SECOND-STAGE

pumping action stops.

HOUSING

5. FIRST-STAGE HOUSING

12. AIR RESERVOIR

b. Pressure Regulator Valve. This component (fig.

TANK

6. CHECK VALVE

13. SLIDING

valve to a predetermined amount, regardless of the

DISTRIBUTOR

pressure in the reservoir. The valve is nonadjustable

7. SECOND-STAGE END

VALVE

and must be replaced if proper pressure is not

OF PISTON

14. ARM

maintained.

Figure

30-17. Air

TA233810

c. Height Control Valve. This valve (fig. 30-19) is

attached to the frame of the vehicle, and linkage is used

to attach the valve to the suspension system. When the

frame moves downward because of additional weight,

30-12

|

||

|

||