| Tweet |

Custom Search

|

|

|

||

TM 9-8000

start, therefore the brakes harness eight times the power

c. Overall radius of wheel (distance from center of

developed by the engine. Thus, about 640 (8 x 80) hp

wheel to outer tread of tire).

has to be spent by the friction surfaces of the brakes of

an average passenger car to bring it to a stop from 80

d. Radius of brake drum or rotor (rotating member).

mph in 4.5 seconds.

e. Coefficient of friction between braking surfaces.

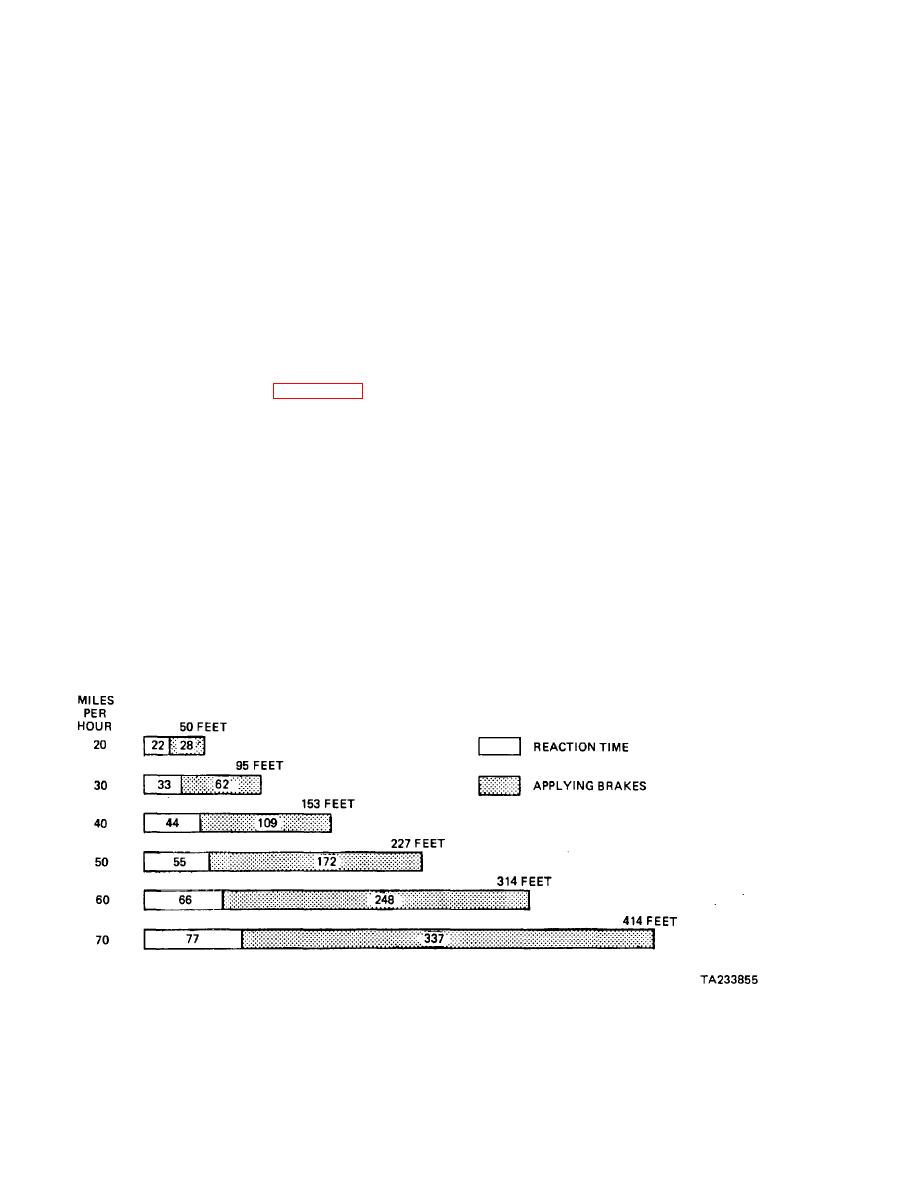

34-3. Vehicle Stopping Distance. Driver reaction time

f. Coefficient of friction between tire and road.

is the time frame between the instant the driver decides

that the brakes should be applied and the moment the

When the radius of the wheel or weight of the vehicle is

brake system is activated. During the time that the driver

increased, the pressure required on braking surfaces

is thinking of applying the brakes and moving his or her

also will be increased for a fixed amount of retardation.

foot to do so, the vehicle will move a certain distance,

These factors are independent of the design of the

depending on its speed. After the brakes are applied, the

braking system and generally are a fixed value.

vehicle will travel an additional distance before it is

However, limitations of these factors, particularly the

brought to a stop. Total stopping distance of a vehicle is

weight of the vehicle to be carried by the wheels, must

the total of the distance covered during the driver's

be considered when designing a braking system. If the

reaction time and the distance during which brakes are

radius of the brakedrum or coefficient of friction between

applied before the vehicle stops. Figure 34-3 illustrates

the braking surfaces is in- creased, less pressure will be

the total stopping distance required at various vehicle

required to obtain the same degree of retardation. The

speeds, assuming an average reaction time of 3/4

best results are obtained when these factors are

second and that good brakes are applied under most

correlated within the limits permitted by the design of the

favorable road conditions.

braking system. The coefficient of friction between tire

and road determines maximum retardation obtained by

34-4. Factors Affecting Retardation. The amount of

the application of brakes.

retardation obtained by the braking system of a vehicle is

affected by several factors. For wheel brakes used on

34-5. Maximum Retardation Point. When brakes are

motor vehicles, these factors are:

applied, the wheel either will roll or skid, depending on

relative values of coefficients of friction between braking

a. Pressure exerted on braking surfaces (rotating

surfaces and between tire and road. Heavy jamming of

and non-rotating members).

the

braking

b. Weight carried on wheel.

Figure 34-3. Total Vehicle Stopping Distance of an Average Vehicle.

34-2

|

||

|

||