| Tweet |

Custom Search

|

|

|

||

TM 9-8000

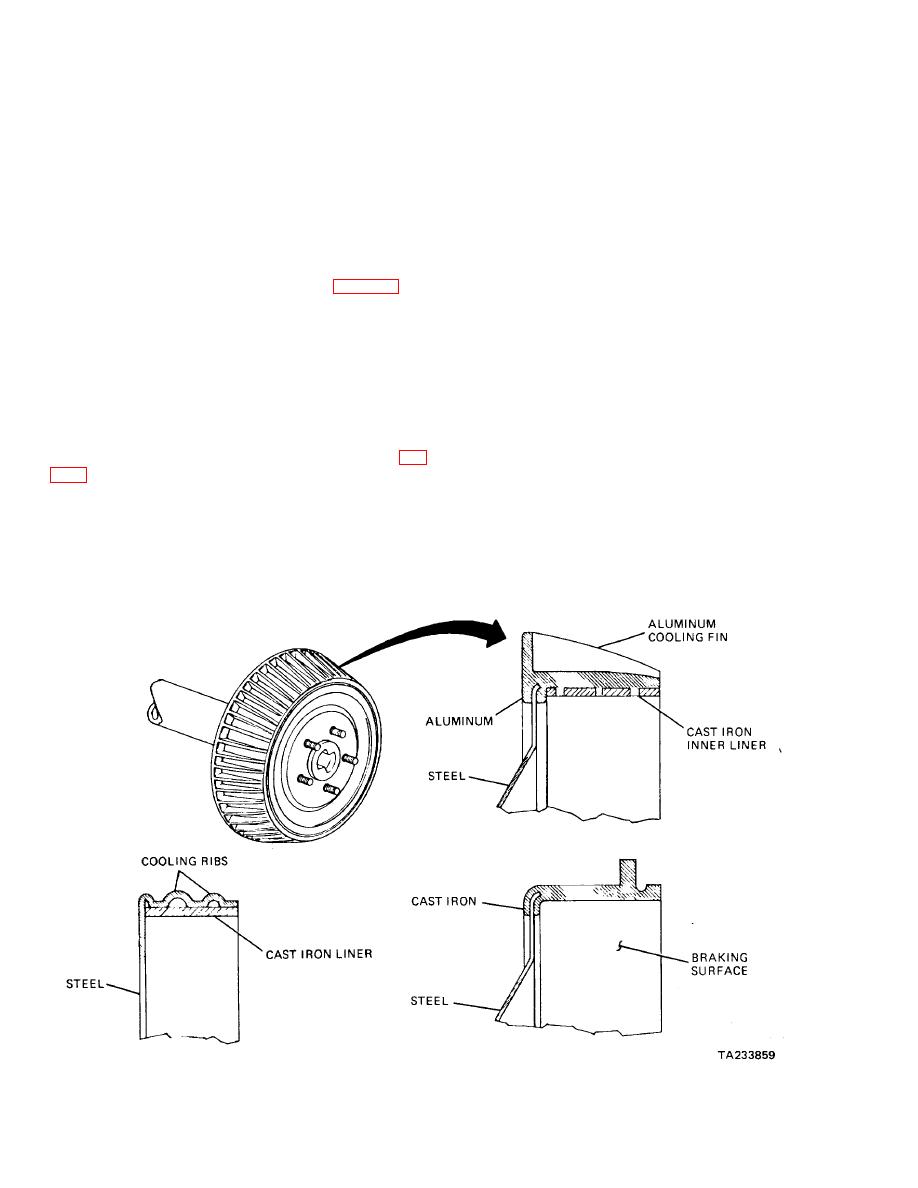

mate with a lip on the backing plate that provides the

minimize brake fade. For good braking action, the drum

rotating seal to help keep water and dirt from entering

should be perfectly round and have a uniform surface.

the brake assembly. Brakedrums may be made of

Brakedrums become out-of- round from pressure

pressed steel, cast iron, a combination of the two metals,

exerted by brakeshoes and from heat developed by

or aluminum. Cast iron drums dissipate the heat

application of the brakes. The brakedrum surface

generated by friction faster than steel drums and have a

becomes scored when it is worn by braking action. When

higher coefficient of friction with any particular brake

the surface is scored or the drum is out-of- round, it may

lining. However, cast iron drums of sufficient strength are

be necessary to machine the brakedrum until it is

heavier than steel drums. To provide lightweight and

smooth and true again. Care must be taken not to

sufficient strength, centrifuse brakedrums (fig. 34-7),

exceed the maximum allowable diameter according to

made of steel with a cast iron liner for the braking

manufacturer's specifications. If this caution is ignored,

surface, are used. A solid cast iron drum of the same

the drum can be distorted easily due to

total thickness as the centrifuse drum would be too

overheating, and result in brake failure. Each drum is

weak, while one of sufficient strength would be too heavy

stamped with the maximum diameter information and, if

for the average passenger car. Aluminum

exceeded, it should be discarded and replaced with a

brakedrums are constructed similar to the centrifuse

new one.

drums. They consist of an aluminum casting with a cast

Iron liner for a braking surface. This design allows heat

34-8. Hydraulic Actuation. The hydraulically operated

to be transferred to the surrounding atmosphere more

service brake uses fluid pressure to operate a hydraulic

readily and also reduces weight. Cooling fins or ribs (fig.

cylinder, which in turn operates the brakeshoes. The fluid

pressure is generated by a hydraulic system whose

ribs increase the surface area of the outside portion of

operation is discussed in paragraph 34-23.

the brakedrum, allowing the heat to be transferred to the

atmosphere more readily, thereby keeping the drum

349. Pneumatic Actuation. The pneumatically actuated

cooler and helping to

service brake uses a controlled, compressed air supply

from the air system as de-

Figure 34-7. Brakedrum Construction

34-6

|

||

|

||