| Tweet |

Custom Search

|

|

|

||

TM 9-8000

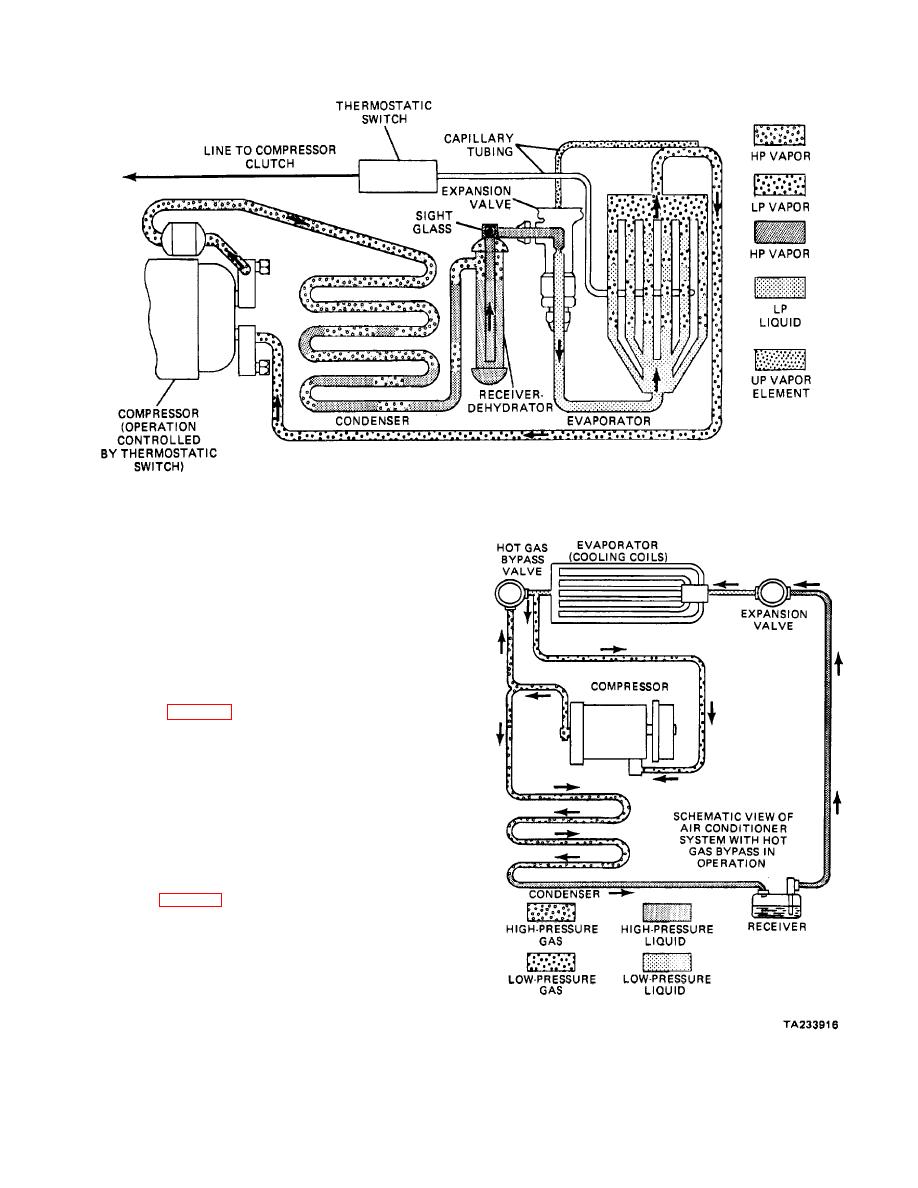

Figure 37-6. Thermostatic Evaporator.

engage and disengage the compressor. The switch is

operated by a sensing bulb placed in the airstream after

the evaporator. As the evaporator temperature falls, the

thermostatic switch opens to disengage the magnetic

clutch in the compressor. When the coil temperature

reaches the proper level, the switch again closes to

engage the clutch and again drive the compressor.

b. Hot Gas Bypass Valve. The hot gas bypass

valve was used on some older models to control

evaporator icing (fig. 37-7). The valve is mounted on

the outlet side of the evaporator. The high-pressure gas

from the compressor Joins with the low-pressure gas

exiting the evaporator. These two gases mix, causing a

pressure increase. The boiling point also increases,

resulting in a loss of cooling efficiency. This, in turn,

causes the evaporator temperature to increase, thus

eliminating freezeup. The compressor is designed to run

constantly (when it is activated) in the hot gas bypass

valve system.

c. Suction Throttling Valve. The suction

throttling valve (fig. 37-8) is used now in place of the hot

gas bypass valve system. It is placed in line with the

outlet of the evaporator. This system is designed to limit

the amount of low-pressure vapor entering the

compressor. The suction throttling valve operates as

follows:

Figure 37-7. Hot Gas Bypass Valve.

37-7

|

||

|

||