TM 9-2815-202-34

4-33.

(6)

(7)

(8)

(9)

(10)

(11)

PISTON AND CONNECTING ROD MAINTENANCE (Cont)

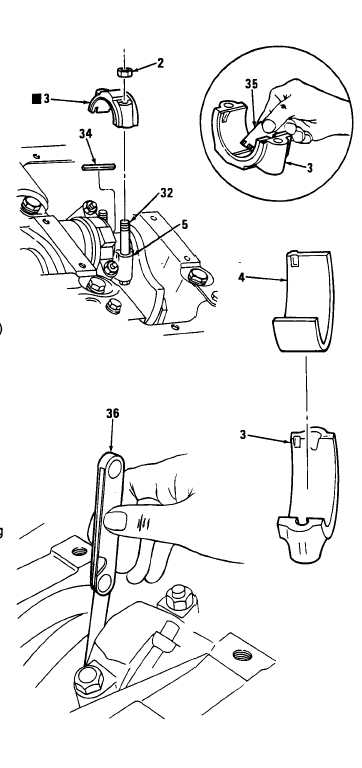

Check bearing to crankshaft journal

clearance by placing a plastic gage strip

(34) between crankshaft journal (32) and

connecting rod cap (3). Tighten connecting

rod nuts (2) to 60-70 Ib-ft (81-95 N-m.).

Remove connecting rod nuts and cap, and

measure width of plastic gage with

measuring strip (35). Maximum clearance

with used parts is 0.006 inch.

Place lower bearing shell (4) in connecting

rod cap (3). Lubricate bearing shell with

clean engine oil.

NOTE

Ensure connecting rod bolt has

not turned in connecting rod

before torquing nuts.

Install bearing cap (3) and bearing shell (4)

on connecting rod (5) with identification

numbers on cap and rod adjacent to each

other. Torque connecting rod bolt nuts (2)

to 60-70 Ib-ft (81-95 N.m.).

NOTE

If necessary, pry connecting

rods apart before measuring

side clearance.

Using feeler gage (36), measure side

clearance between each pair of connecting

rods. Clearance limits are 0.008 to 0.016

inch.

Install additional liners, pistons, and rod

assemblies in same manner. Use

hold-down clamps to hold each liner in

place.

Remove all liner hold-down clamps.

END OF TASK

FOLLOW-ON MAINTENANCE

Para Description

4-32 Install oil pump and oil pump tubes

4-31 Install oil pressure regulator and

relief valve

4-27 Install cylinder head

4-20 Install oil pan

I

4-144

C h a n g e 1

|

|