TM 9-2815-225-34&P

3-92. ENGINE DYNAMOMETER TESTING (Contd)

LOCATION/ITEM

ACTION

REMARKS

e. Final Check (Contd)

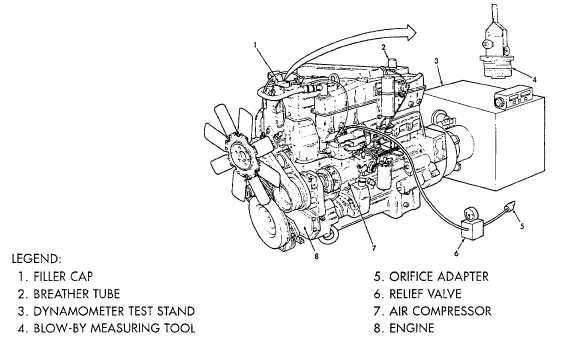

16. Orifice adapter (5) and

Remove from air compressor

air compressor (7)

relief valve (6).

17. Blow-by measuring tool (4)

Remove from engine (8) and

and manometer

install filler cap 1).

18. Breather tube (2)

Unplug.

NOTE

At each phase, record crankcase pressure (blow-by), engine speed, and load at one minute

intervals. Watch for increases or wide shifts in blow-by pressure. If sudden increase

happens, or if it is more than 12" H2O, do the preceding test over again and run engine 15

more minutes. When blow-by is OK, do next test. If not OK, stop the test and find reason

for too much blow-by. Check engine for fuel, oil, water, air, or exhaust leaks after each test

and fix as needed.

Phase 1 - 25% HP @ 1200 RPM @ 160 water temperature.

Phase 2 - 40% HP @ 1200 RPM

Phase 3 - 65% HP @ 1600 RPM

Phase 4 - 100% HP @ Nominal torque peak RPM *(1200) RPM

Power Check - 96-100% HP @ 1600 RPM

*100 RPM below torque peak RPM

FOLLOW-ON TASK:

Perform on-engine fuel pump adjustment (para. 3-93).

Table 3-1. Dynamometer Test Chart

ENGINE HP @ RPM

RATED

HP @ RPM

500 FT-ALT

FUEL

RATE

LB/HR

AIR MANIFOLD

PRESSURE

IN/HG

ALTITUDE

MAX. HP

ALT.

CRANKCASE

PRESSURE

W/TURBO T46B

PHASE 1

TO 160f

HP @ RPM

PHASE 2

2 MIN.

HP @ RPM

PHASE 3

5 MIN.

HP @ RPM

PHASE 4

4 MIN.

HP @ RPM

POWER

CHECK

4 MIN.

HP @ RPM

NTC

400

400 @

2100

400 @

2100

139-145

39/47

12,000

12" H2O

100 @

1200

160 @

1200

260 @

1600

Full Load

@ 1200

384 @

2100

3-689

|

|