| Tweet |

Custom Search

|

|

|

||

TM 9-8000

c. Valve Seats (Fig. 3-48). valve seats are very

Section III. 3-12. Valves and Seats.

important, as they must match the face of the valve

head to form a perfect seal. The seats are made so that

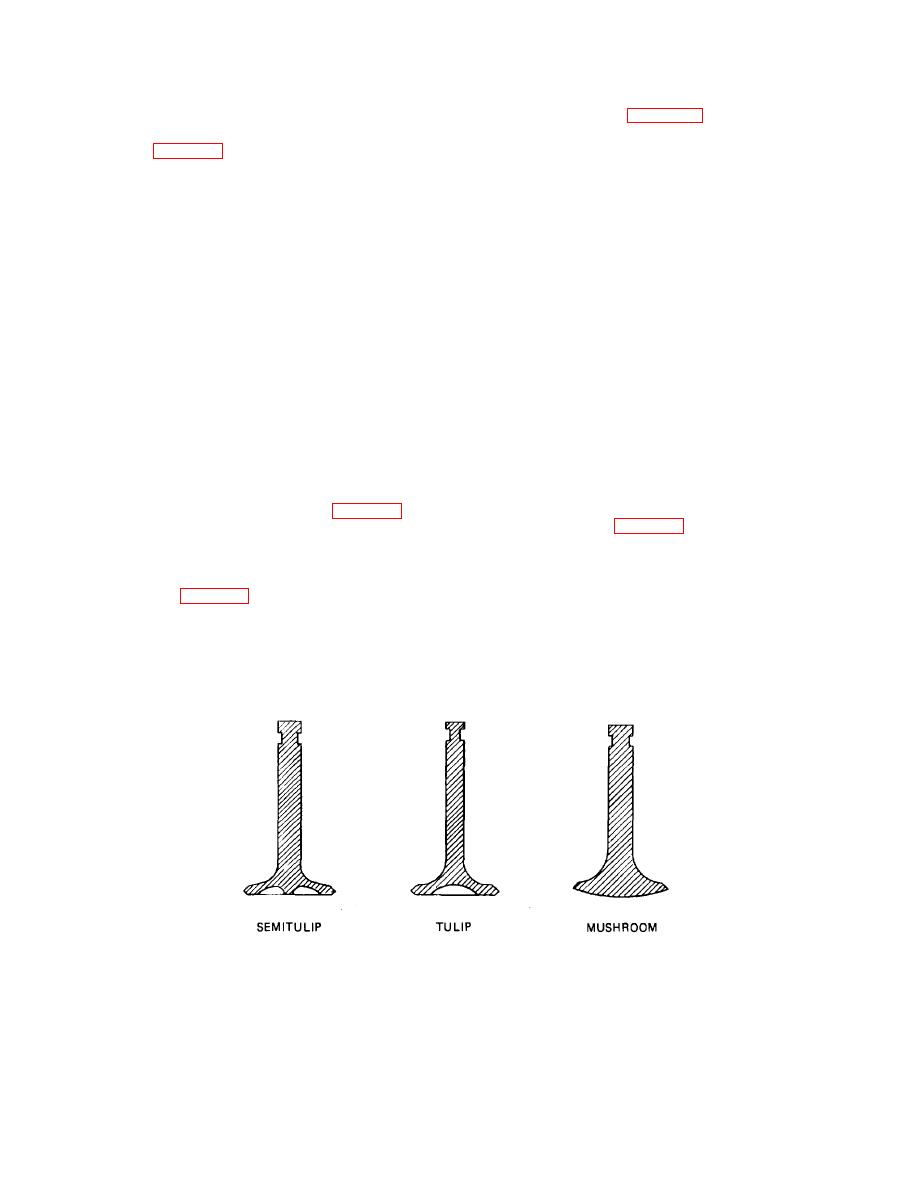

a. General (Fig. 3-46). Each cylinder in a four-stroke

they are concentric with the valve guides; that is, the

cycle engine must have one intake and one exhaust

surface of the seat is an equal distance from the center

valve. The valves that are commonly used are of the

of the guide all around. There are two common angles

poppet design. The word poppet is derived from the

that are used when machining the valve seat; they are

popping action of the valve. Poppet-type valves are made

30 and 45 degrees. The face of the valve is usually

in the following three basic shapes: the mushroom,

ground with a one-half to a 1-degree difference to help

semitulip, and tulip. The valve shape that is used in a

the parts seat quickly. In some cases, a small portion of

given engine is dependent upon the requirements and

the valve seat has an additional 15- degree angle

combustion chamber shape.

ground into it to narrow the contact area of the valve

face and seat. By reducing the contact area, the

b.

Construction.

Construction

and

design

pressure between the mating parts is increased,

considerations are very different between intake and

thereby forming a better seal. The valve seats can be

exhaust valves. The difference is based on their

either part of the cylinder head or separate inserts.

temperature operating ranges. Intake valves are kept

Valve seat inserts generally are held into the head by an

cool by the incoming Intake mixture. Exhaust valves are

interference fit.

subject to intense heat from the burnt gases that pass by

it. The temperature of the exhaust valve can be in excess

The head is heated in an oven to a uniform high

of 13000F (704.40C). Intake valves are made of a nickel

temperature and the seat insert is shrunk by cooling it in

dry ice. While the two parts are at opposite temperature

alloy. In certain heavy-duty water- cooled and most air-

extremes, the seat insert is pressed into place.

cooled engines, the exhaust valves are hollowed out and

filled partially with metallic sodium (B, fig. 3-47). The

d. Valve Guides (Fig. 3-49). The valve guides are the

sodium, which liquefies at operating temperatures,

parts that support the valves in the head. They are

splashes between the valve head, where it picks up heat,

machined to a fit of a few thousandths of an inch

and the valve stem, where the heat is transferred to the

clearance with the valve stem. This close clearance is

valve guide. Some exhaust valves use a special hard

important for the following reasons:

facing process (A, fig. 3-47) that keeps the face of the

valve from taking on the shape of the valve seat at high

(1) It keeps the lubricating oil from getting

temperatures.

Figure 3-46. Valve Configurations

3-27

|

||

|

||