| Tweet |

Custom Search

|

|

|

||

TIM 9-8000

tappets or the lifters are the connecting link

between the camshaft and the valve

mechanism.

b. Camshaft Construction. Camshafts usually are made

from cast or forged steel. The surfaces of the lobes

are hardened for long life.

c. Camshaft Support (Fig. 3-52). The cam-shaft is

supported, and rotates, in a series of bearings along

its length. The bearings usually are pressed into their

mountings and made of the same basic construction

as crankshaft bearings. In some cases, when the

engine is constructed of aluminum, the camshaft is

supported directly in its mountings and no bearings

are used. The thrust, or the back and forth

movement, usually is taken up by the thrust plate,

which bolts to the front of the engine block. Any

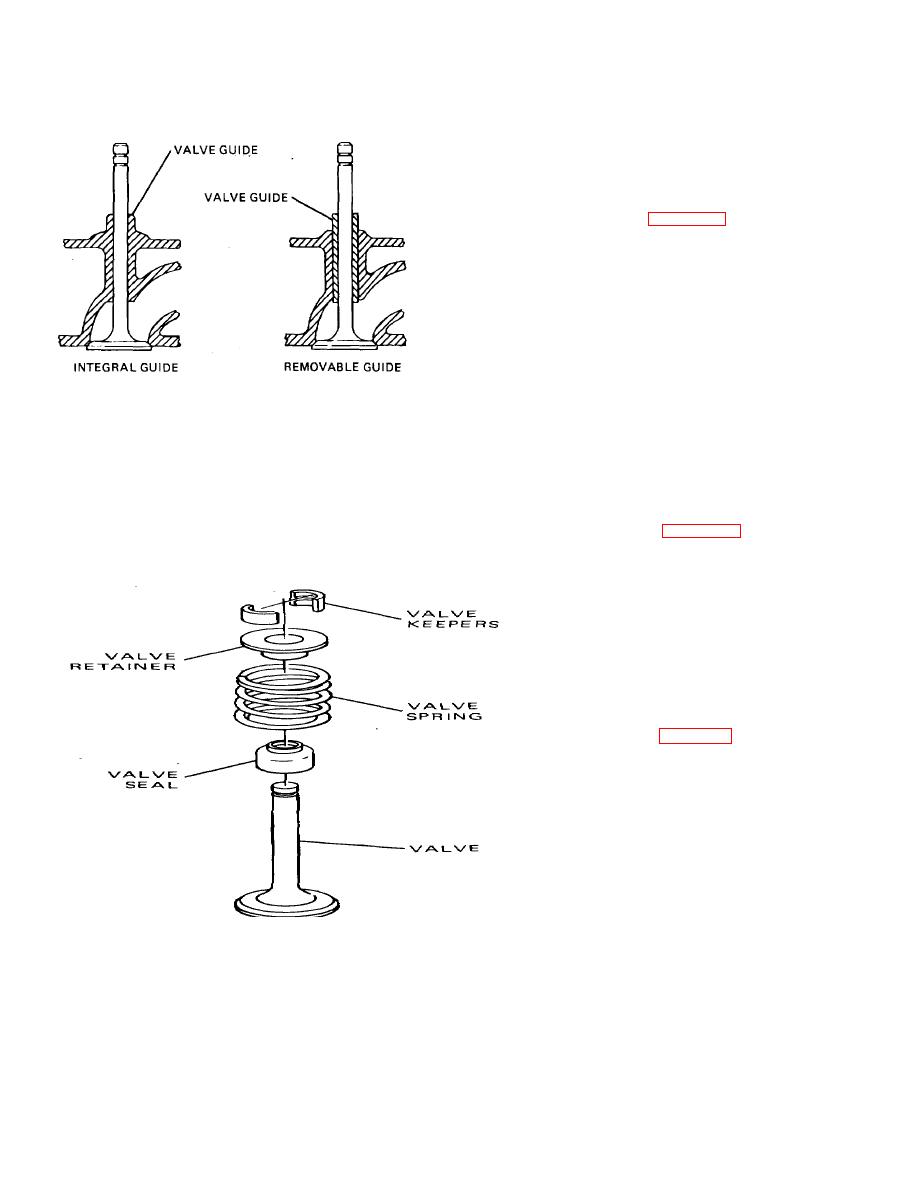

Figure 3-49. Valve Guides.

forward thrust loads are then taken up by the front

camshaft bearing journal. The drive gear or sprocket

flexible washer between the two pieces. A series of balls

then is bolted to the front of the camshaft. Its rear

between the retainer pieces roll on machined ramps as

surface rides against the thrust plate to take up any

pressure is applied and released from the opening and

rearward thrust.

the closing of the valve. The movement of the balls up

d. Driving the Camshaft. The following are the three

and down the ramps translates into rotation of the valve.

basic configurations for driving the cam-shaft.

3-13. Camshafts and Tappets.

a. General. The camshaft provides for the opening and

(1) Gear Drive (A, Fig. 3-53). A gear on the

closing of the engine valves. The

crankshaft meshes directly with another gear on

the camshaft. The gear on the crankshaft usually

is made of steel, while the gear on the camshaft

may be steel for heavy-duty applications, or it

may be made of aluminum or pressed fiber

when quiet operation is a major consideration.

The gears are helical in design (para 19-4).

Helical gears are used because they are

stronger, and they also tend to push the

camshaft rearward during operation to help

control thrust.

(2) Chain Drive (B, Fig. 3-53). Sprockets on the

camshaft and the crankshaft are linked by a

continuous chain. The sprocket on the

crankshaft usually is made of steel, while the

sprocket on the camshaft may be steel for

heavy-duty applications. When quiet operation is

a major consideration, an aluminum sprocket

with a nylon covering on the teeth is used. There

are two common types of timing chains. One is a

silent link-type chain that is used in standard and

light-duty applications. The other is the roller-link

chain, which is used in heavy-duty applications.

The

Figure 3-50. Valve Springs, Retainers,

TA233379

and Seals.

3-29

|

||

|

||