| Tweet |

Custom Search

|

|

|

||

TM 9-8000

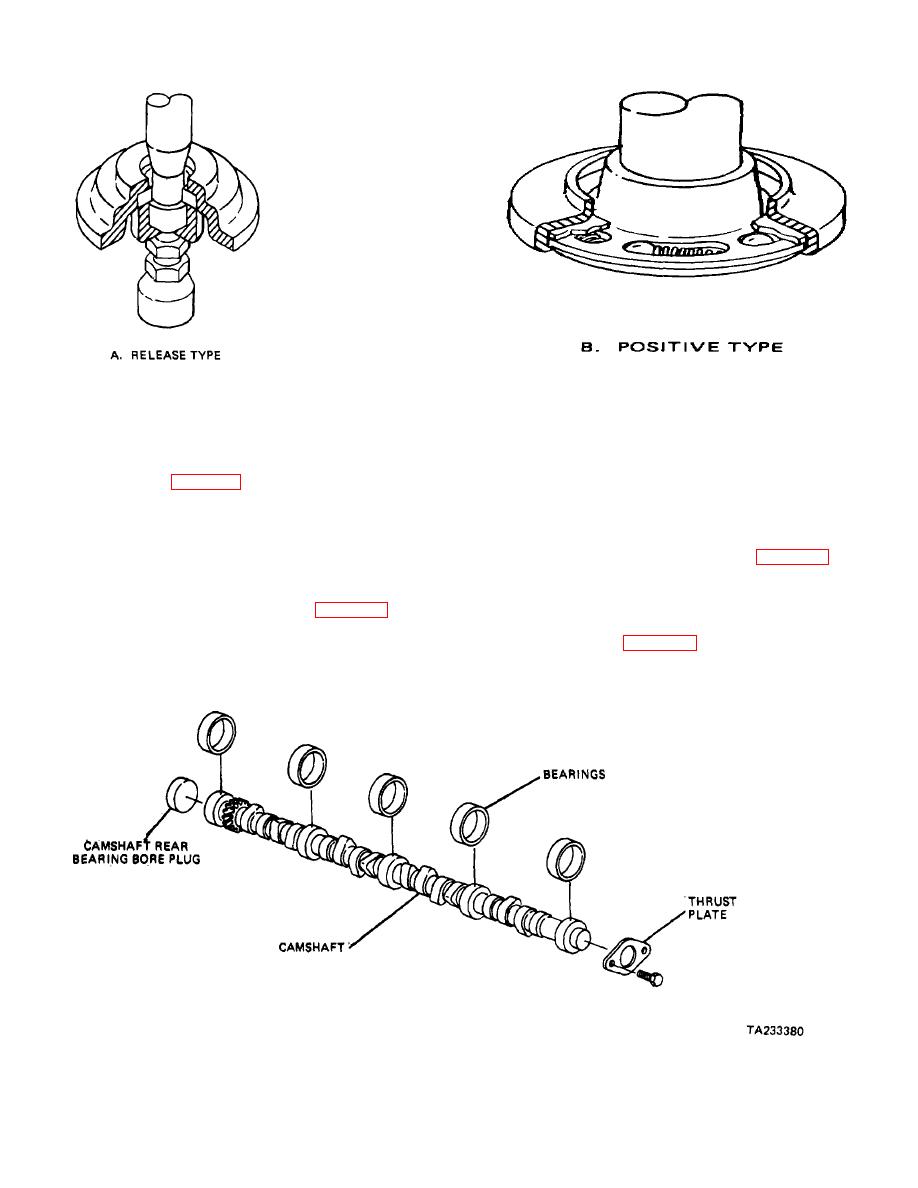

+Figure 3-51. Valve Rotators.

roller link chain may have a single or a double row of

slipping on the sprockets, provide more precise

links.

valve timing, and compensate for component stretch

and wear. Engines with belt-drive configuratlons

(3) Belt Drive (C, Fig. 3-53). Sprockets on the crankshaft

usually use a spring-loaded idler wheel. Chain-

and the camshaft are linked by a continuous neoprene

driven configurations usually use a fiber rubbing

belt. The belt has square-shaped Internal teeth that

block that Is either spring loaded or hydraulic. The

mesh with teeth on the sprockets. The timing belt is

hydraulic tensioner Is a device that works by the

reinforced with nylon or fiberglass to give It strength and

same principle as a hydraulic lifter (para 3-13h(2)).

prevent stretching. This drive configuration Is limited to

The hydraulic tensioner Is much more desirable for

overhead camshaft engines.

use with a rubbing block because it takes up the

slack in the chain without exerting excessive

e. Timing Belt and Chain Tensioners (Fig. 3-53). Most

pressure, resulting in longer component life.

engines with chain-driven and all engines with belt-

f.

Timing Marks (Fig. 3-53) The camshaft and the

driven camshafts employ a tensioner. The tensioner

crankshaft always must remain In the same relative

pushes against the belt or chain to keep It tight. This

position to each other. Because the

serves

to

keep

It

from

Figure 3-52. Camshaft Support.

3-30

|

||

|

||