| Tweet |

Custom Search

|

|

|

||

TM 9-8000

19-11. Oil Seals. Oil seals used in the automotive

assembly are designed to prevent leakage be- tween

rotating and nonrotating members. Two basic types of oil

seals are used on today's vehicles. Each Is discussed

below.

a. Synthetic Rubber Seals. The synthetic rubber

oil seal (fig. 19-14) is the most common type of oil seal.

It is composed of a metal case used to retain its shape

and maintain rigidity. A rubber element Is bonded to the

case, providing the sealing lip or lips that rub against the

rotating shaft. Different types of oil seal designs are

illustrated in figure 19-14. A coil spring, some- times

called a garter spring, also is used to hold the rubber

element around the shaft with a con- trolled amount of

force. This allows the seal to conform to minor shaft

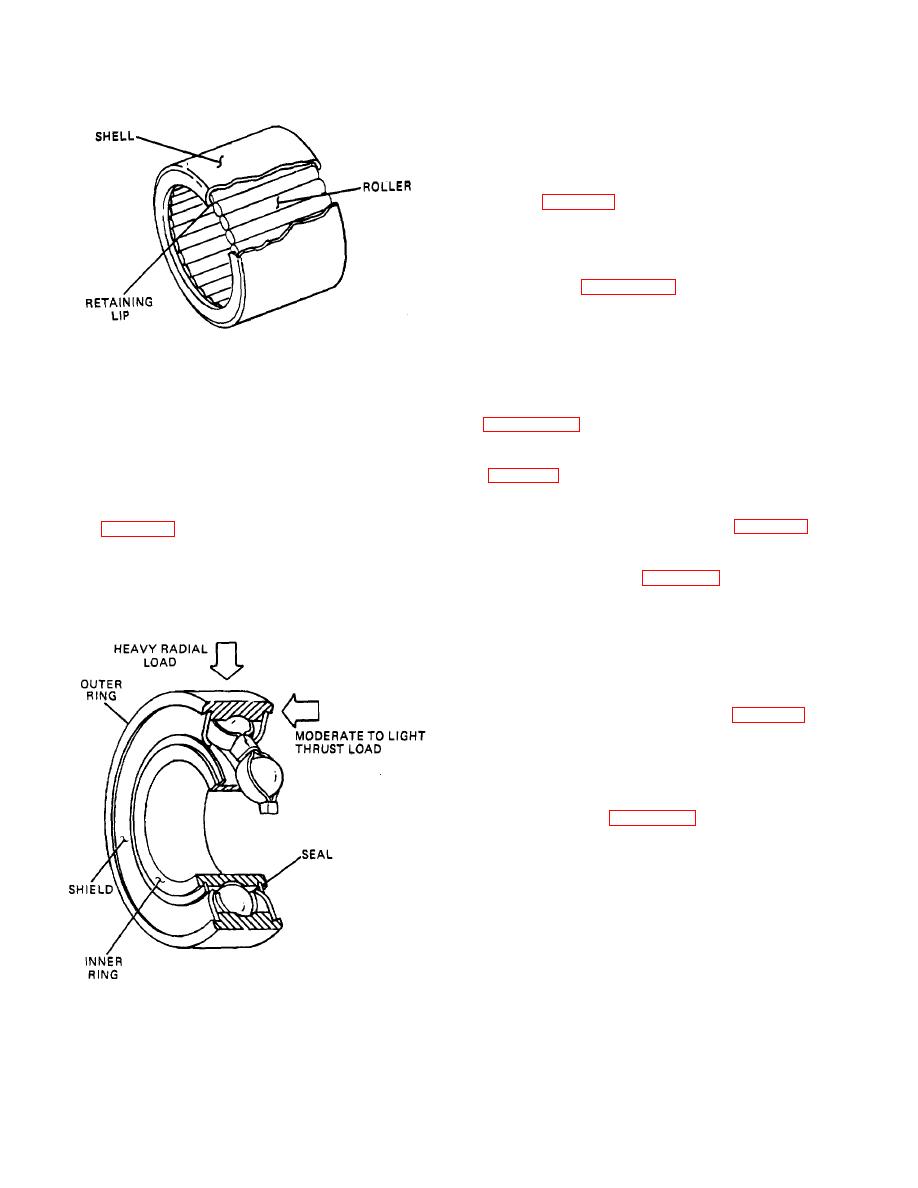

Figure 19-12. Typical Needle Bearings.

runout. Some synthetic rubber seals fit into bores

mounted around the shaft. This type Is generally a split

clutches, transmissions, universal joints, transfer cases,

design and does not require a metal case or garter

or rear axles. If these assemblies are lubricated in

spring. Some oil seals rely on pressure to aid In sealing.

accordance with the specifications as set forth in the

applicable technical manual, and with the lubricant

seals. Internal pressure developed during operation

prescribed for each, the bearing requirements will be

forces the sealing lips tighter against the rotating shaft

satisfied.

against fluid pressure from one direction. Leather also is

used as a lip seal. In this configuration, the seal Inside

sealed at the factory and require no further lubrication. A

diameter is smaller than the shaft (fig. 19-14). As the

shield (fig. 19-13) is used to contain the lubricant and

shaft is Installed, the seal bows outward to form a lip

prevent foreign matter from entering the bearing. These

seal.

bearings generally are used when Inherent lubrication is

b. Wick Seals (Fig. 19-15). The wick seal made

not available or a dirty operating environment must be

of graphite-impregnated asbestos wicking sometimes Is

overcome

used to control oil leakage. This seal conforms to the

recess In which it Is Installed. When using this type of

seal, a knurled finish is used on the rotating shaft. The

oil Is contained between the knurls and seal, which rub

together. As the shaft rotates, the oil is driven back by the

propeller effect of the seal and knurl finish. An oil slinger

sometimes Is used with wick seals (fig. 19-15). The oil

slinger is a raised washerlike area on the shaft. As oil

meets the slinger, it is propelled outward by centrifugal

force. A catch trough then Is used to collect the oil and

return it to the sump.

known as static seals, are used to form pressure-tight

Joints between stationary members. They usually are

made of a deformable material In the shape of a sheet or

ring, which

Figure 19-13. Typical Sealed Bearings

TA233660

19-11

|

||

|

||